| SJ23 Tech Tip F02, (Updated 2021-05-24) Bob Schimmel | |

|

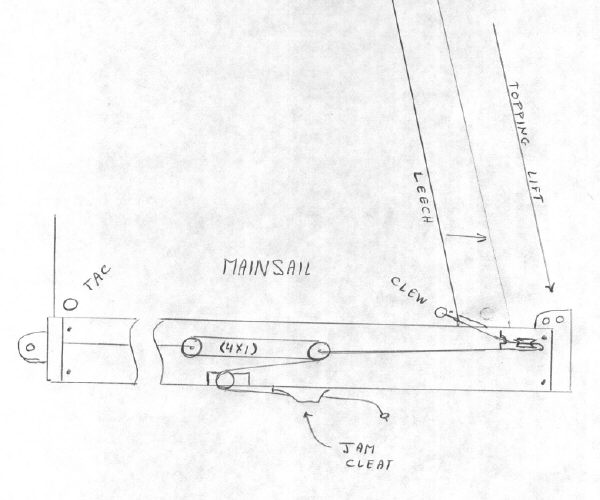

Boom Internal Outhaul - Flatten Mainsail & install to shorten boom. |

|

Panache's

boom was way too long for the foot of my new full-batten mainsail,

extending about 1.5' beyond the clew. My

suspicion is that, due to it's early hull vintage, the boom was long

to match the factory mainsail of the time. The long boom is clearly visible on a

1977 brochure showing an SJ23 on a spinnaker run. This boom would sweep clear across

the cockpit, whacking your head. I vaguely remember reading somewhere that one of the Clarks realized this and shortened the

boom. Something about, "There should be a place to stand where the boom can't whack you!" Panache's

boom was way too long for the foot of my new full-batten mainsail,

extending about 1.5' beyond the clew. My

suspicion is that, due to it's early hull vintage, the boom was long

to match the factory mainsail of the time. The long boom is clearly visible on a

1977 brochure showing an SJ23 on a spinnaker run. This boom would sweep clear across

the cockpit, whacking your head. I vaguely remember reading somewhere that one of the Clarks realized this and shortened the

boom. Something about, "There should be a place to stand where the boom can't whack you!" The section of boom protruding beyond the clew supported an external block & tackle to tension the mainsail foot. The problem with the protruding section on Panache is that I sometimes didn't see it coming across. Yikes! I guess this is why its called a boom? The prospect of it whacking my head was not something I looked forward to on my outings. Since I've had far too many close calls and lost too much coffee, I shortened the boom 9" so now it extends only 6" past the clew. Shortening the boom solved one problem. It also necessitated an internal outhaul due to the reefing lines installed on the outside of the boom.

At left is the exit block of the outhaul line at the bottom of the (mid) boom. At right is the shortened boom showing the entry block of the outhaul line. Construction

Conclusion

-

With the shorter boom I can now stand astride the tiller, steering with

my knees and focus on where I'm going without fear of a concussion from

the boom. I can also finish my coffee to the last drop! With the outhaul adjustment in

the middle of the boom, I can adjust the tension on all points of sail except downwind, thereby maintaining sail balance and drive. There is sufficient mechanical

advantage to tension the foot of the mainsail well beyond what is

required. You don't have to be a deck ape to perform this job! The only

problem I've experienced, is dealing with the internal friction to

release the tension for light air sailing. This merely requires that I

pull some slack into the line and push the foot of the mainsail forward.

(Seems like a dumb thing to say but it works).

NOTE -

Unfortunately I can only guess at what the factory version of the outhaul line

looks like. Panache did have a block and tackle between the clew and the end

of the boom but it was not factory hardware. The previous owners of Panache changed this long

before I bought her.

This is a similar system to what

Panache had.

|

|

|

Return to Tech Tip Index. . . . . . . . . . . . . . . Have a Question? |

|