| SJ23 Tech Tip A05, (Updated 2025-05-14) Bob Schimmel | |

|

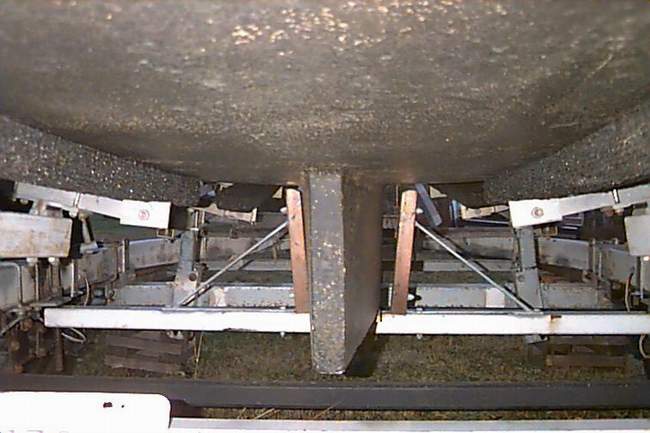

SJ23 Trailer Keel Guides for Lateral Weight Distribution, (1999). |

|

| This

is a photo of Panache's keel guides. They ensure the hull is

centered on the trailer so the tires of the single axle (3500 lbs) carry equal load and the hull doesn't

rub against a trailer fender. Equal weight on each tire is

crucial for a single axle that is loaded to rated capacity. The

steel guides are bolted on the

adjustable keel support bar and are lined with cedar 2x4s to protect the

gel coat. The starboard guide leans over a bit further than the port

guide so the keel support bar can be lowered for launching and retrieval. The (1.5x3)" keel

support bar

pivots on a 3/4" bolt on the starboard side of the trailer and is adjusted up &

down with a 3/4" screw jack on the port side. You can see the jack

screw protruding through the bar on the left side of the picture. Just

barely visible below the keel is a wood support pad.

Dirty wet cedar can be slippery but clean wet cedar is usually sticky, similar to the good traction you can get with clean deck shoes on wet gel coat. The problem is cedar will be clean & "sticky" when the trailer is immersed, resulting in the keel tending to "stick" instead of sliding down the guide to rest on the support bar. When this happens the hull doesn't center on the trailer. (i.e.: doesn't rest equally on all support pads) and there is a lot of side loading on the keel for the rest of the winter. I solved this problem by lining the cedar keel guides with slippery 1/4" thick puck board. This made the gap slightly narrower which is not a problem. The keel now slides freely down the guide when the boat is retrieved. Alternatively you could use slippery UHMW, Teflon or nylon. Remember to round the corners of the sheeting. No point in solving one trouble and then creating another! Puck board stands up very well to impact in cold weather. After all, the boards of all Canadian hockey rinks are lined with this stuff.

In the remake of these guides I left a 1/4" air gap at the bottom of the wood and a 1" gap of puck board at the bottom so the wood can drain drip dry. I never allowed for enough drainage in my original fabrication. Finally the wood received a coat of Sikkens Cetol.

Also

see guide posts in Tech Tip A01. |

|

|

Return to Tech Tip Index. . . . . . . . . . . . . . . Have a Question? |

|

The keel is 7.25" thick at its

widest point which is

located just aft of the forward end of the large cabin window.

The keel is 7.25" thick at its

widest point which is

located just aft of the forward end of the large cabin window.