The vast majority of trailerable pocket cruisers leave the factory with only a basic fibreglass finish in the cabin. The main reason you couldn't afford a cruiser with a finished cabin is due to the time and expense it takes to complete the detailed work. For this reason the cabin sole of a production boat is usually

finished in non-skid gel coat. This is a practical cost effective compromise that also allows the owner to add their personal touch. Unfortunately lots of boats end their life in this state, looking rather stark and clinical. On the flip side there are boats that stand out for the upgrade to their cabin sole. Just like in a house, the floor is a major attraction.

If you do this upgrade well, your boat will appreciate it and your friends will be in awe as they board. If you do this upgrade well, your boat will appreciate it and your friends will be in awe as they board.

A flat sole is fairly easy to cover while a concave floor requires skill to fit rigid plywood. Mess this up and you will have to replace the material, unless you are clever enough to hide your mistake. This sometimes leads to a crafty solution, but I digress.

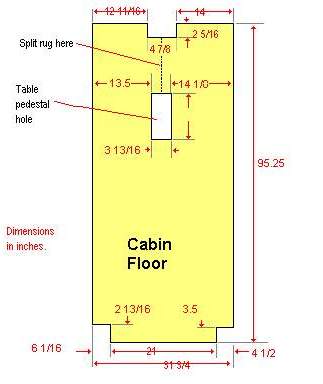

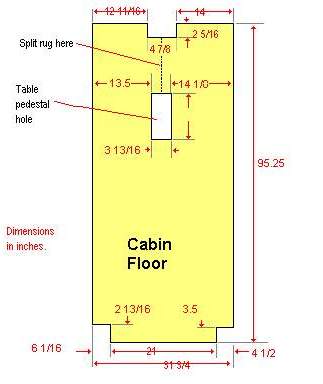

Cabin Sole - Just

in case you have a burning desire to add a teak and holly sole to your

SJ23, the dimensions are shown at left. I used these as a guide to cut a rug for Panache so I know they are correct. Cabin Sole - Just

in case you have a burning desire to add a teak and holly sole to your

SJ23, the dimensions are shown at left. I used these as a guide to cut a rug for Panache so I know they are correct.

(Thanks to Art Brown for preserving the original diagram from the Seattle SJ23 Club.)

A hardwood sole would certainly add class to your craft and is easy to sweep clean. Teak and holly 1/4" plywood is available in a (4x8)' sheet or you can make your own floor as shown on my buddy's Aloha 27 at right. That was a winter long job requiring accurate templates, cutting strips of mahogany and finally edge gluing the strips into a sheet for installation. He made extensive use of his cardboard templates since it required meticulous accuracy. If you mark your cuts on masking tape you won't leave marks on the wood. The tape will protect the plywood from the saw and helps to prevent tear outs while cutting. For the round corners use a double edged blade (cuts up & down) on your jig saw with light pressure on the blade to make a glass smooth cut without tear outs. The finished cut is impressive to see.

The one draw back of a wood sole is the possible damage when it is immersed. I'll let you dwell on your own experience of how water entered your hull! Even ankle deep water is enough to cause a problem. We all know that an incident like this can happen so for best protection the wood should be saturated in epoxy followed by varnish for that warm feeling under foot. If you remove the water the same day and start ventilating the cabin, the wood sole should be OK. Scratches from daily wear or sand covered feet can be removed with an annual coat of varnish. My buddy's custom mahogany floor at right was glued to the gel coat with Sikaflex and is unlikely to be damaged if immersed. It is so solid under foot that it looks and feels like factory original. It really is the wow factor as you step inside.

On Panache I installed heavy duty indoor/outdoor rug with rib backing so the rug can more easily survive a soaking should the cabin sole gets wet. After all, it is a pocket cruiser that can be beached and swimmers have a nasty habit of coming onboard with sand stuck to their wet feet! I've always banked on the fact that water can evaporate from under the rug, albeit slowly, or the rug can be removed for drying in the sun. The ribbed surface does a good job of

trapping dust or sand, preventing it from spreading. Sometimes the ribs trap the dirt all too well and that is when I roll it up and flip the dust overboard. Back to the beach you go! Although, I recently used a stiff whisk and a Ryobi vacuum to clean the rug. This technique finally picked up the tiny bits of wire from two years of electrical installation work. Any telephone company installer will tell you how difficult it is to pick these up. On Panache I installed heavy duty indoor/outdoor rug with rib backing so the rug can more easily survive a soaking should the cabin sole gets wet. After all, it is a pocket cruiser that can be beached and swimmers have a nasty habit of coming onboard with sand stuck to their wet feet! I've always banked on the fact that water can evaporate from under the rug, albeit slowly, or the rug can be removed for drying in the sun. The ribbed surface does a good job of

trapping dust or sand, preventing it from spreading. Sometimes the ribs trap the dirt all too well and that is when I roll it up and flip the dust overboard. Back to the beach you go! Although, I recently used a stiff whisk and a Ryobi vacuum to clean the rug. This technique finally picked up the tiny bits of wire from two years of electrical installation work. Any telephone company installer will tell you how difficult it is to pick these up.

Ribbed rug like this is sold at most any home improvement store, usually going by the pseudonym of hallway runner. It comes in a 36" wide roll and is relatively easy to cut to shape using heavy duty scissors. It took me only an hour to cut my rug to a perfect fit using the floor pattern above. The split in the rug between the table pedestal and the compression post is almost invisible. After 20 years the rug still looks good as can be seen on the left If you really want to upscale the appearance of your rug, have the edge stitched. Binding, surging or fringing is generally done by a professional with a specialty machine. I've never gotten around to doing this though. Life commitments getting in the way again!

See Tech Tip C01 to enclose the pedestal support post.

"Throne

Room" Sole - The foot well in front of the SJ23 head is tiny (22.5 x

11.25)", perfect for that custom

Persian rug you've always wanted but couldn't afford. This small size should make it affordable and it should only take a month to make! For hygienic reasons I choose to leave the foot well on Panache bare. Besides, a rug this small would require a piece of none skid cloth under it to prevent sliding. I think it's just not worth the trouble and effort. Either hard wood or a stiff rug will greatly improve the traction under foot to make life a little easier in a rough seaway or at anchor. Either wood or rug is warm on the tootsies when spending the night at anchor but I'll have to give a rug the edge here. I don't know about you but I always appreciate a warm floor when I step out of my sleeping bag. It definitely adds that feeling of warmth to the cabin.

Regardless of which upgrade you choose, your boat will likely be the envy of the fleet. __________________________________________

CUSHIONS

- If you still have the factory cushions the foam will have collapsed and sleeping on it is out of the question. Torture comes to mind! I value my back too much to go through this exercise. When selecting new foam, consider the following:

- Combating

mould in moist air - Some foams are better at preventing mould growth than others. You

will have to talk to your local foam expert to elaborate on this

property. But if you have high humidity where you sail I would seriously consider a non-skid grid under the foam to provide air flow.

- Comfort

and support - The foam must be firm to retain it's shape and it must

be able to support an adult so they don't bottom

out while sitting. Closed cell foam doesn't soaks up water and can double as a floatation device, although you will have

a tough time throwing it into the wind! Memory foam (Tempur) is

very comfortable to sleep on. It softens with your body heat

to create a perfectly matched supporting form, relieving a lot of

stress. This means no

hard spots and very little roll if the boat is anchored in a

lumpy bay. However, it is also incredibly expensive if you seldom use the boat overnight. For lifetime

durability select the highest quality foam. This is far cheaper than

replacing the cushions every few years.

- Fabric VS vinyl - Fabric is soft to the touch and breathes moisture, therefore

drier, more comfortable and quieter to sleep on. Vinyl is stain resistant and water proof

making it easy to wipe up food spills and useful in the cockpit where it is exposed

to water. These are two opposing sides of an argument that will likely

never be resolved. Panache's settee cushions are vinyl on the bottom and cloth on

the top. I chose this so I can flip the cushion to match the use; vinyl up for meal time and cloth up for all other times. You

could also cover the cushion with a towel to protect them during meal time

but a towel provides marginal protection against a liquid spill. If I keep the

cabin dry then the vinyl does not sweat against the fibreglass.

- Fit - Cushions should fit snug to the walls so they stay in place when heeled. An extra 1/2" should keep them in place. I regretted making the long settee cushions on Panache as one piece. A split cushion is easier to flip up to access the storage below, especially if a person is sitting on the other end.

- Settee Hole - (9x15)" ea, 3 per side.

- Settee Hole Plug - (11.5x17.5)" ea, 3 per side.

- Fabricate - Box cushion for in cabin. Box cushion with piping for the cockpit, Box cushion with excellent description.

- NOTE - In the settee cushion diagram below the 78" long port cushion fits

Panache due to the galley that takes up 14" of the aft end of the settee. Without this galley the port and starboard settee dimensions are the same.

|

FOAM BUYING GUIDE

Use this chart to help you determine the type of

foam that will best suit your needs. All the urethane based foam listed below pass the flame retardant test for

California 117 and Motor Vehicle Safety Standard 302.

(This guide was emailed to me years ago by an SJ23 owner. Unfortunately he didn't have the retailer's info. However,)

|

|

The following are the High Resilience (HR) foams we stock.

|

ILD

(firmness) |

DENSITY

(weight) |

EXPECTED

RESILIENCE * |

FEEL |

USES |

| 11 |

1.8 |

10 years |

extra soft |

Soft back cushions, envelope down / feather

cushions. |

| 20 |

2.4 |

10 years |

comfort soft |

Medium firm back cushions, XX-Extra soft

seating for furniture. |

| 26 |

2.7 |

10 years |

soft firm |

Back cushions, soft furniture seating. |

| 31 |

2.7 |

10 years |

medium |

Better medium firm seating for furniture.

Exceeds industry standard. |

| 33 |

1.9 |

7 years |

medium firm |

Good medium firm seating for furniture.

This foam is our best seller! |

| 34 |

1.9 |

7 years |

medium firm |

Same great properties as our 3319.

Made with soy for the environmentally aware consumer. |

| 33 |

3.1 |

12 years |

Medium deluxe |

Best medium firm high support seating for

furniture.

This is the best seating foam on the market! |

| 41 |

2.8 |

10 years |

Firm |

Firm seating. Great for dining chairs, boat

or car seats. |

| 61 |

3.0 |

10 years |

Extra firm |

Extra firm seating. Great for snowmobile

seats. |

The following are

the High Density (HD) foams we stock.

|

|

ILD

(firmness) |

DENSITY

(weight) |

EXPECTED

RESILIENCE * |

FEEL |

USES |

| 45 |

2.6 |

5 years |

firm |

Firm seating. Great for dining chairs, boat or car seats. |

The following are

the conventional foams we stock.

|

ILD

(firmness) |

DENSITY

(weight) |

EXPECTED

RESILIENCE * |

FEEL |

USES |

| 19 |

1.1 |

3-5 years |

Soft |

Good soft foam for backs of furniture. |

| 32 |

1.8 |

4 years |

medium firm |

Economy medium firm seating foam. Same

quality as new furniture. |

| 40 |

1.7 |

3-5 years |

firm |

Mattresses, seats of all kinds and many

other applications. |

| 44 |

1.4 |

3-5 years |

firm |

Mattresses, seats of all kinds and many

other applications. |

*Expected Resilience - The expected length of time for a foam to

retain it’s original functionality and stability.*Our foam is

stocked in (24 x 72)” sheets, in an assortment of thicknesses. Please use our catalogue part numbers to order. The part

number tells you the ILD, the density and the thickness of the

foam. For example, our best selling foam is #33194:

|

| ILD - 33 |

DENSITY - 1.9 |

THICKNESS - 4 |

Order with

this part # - 33194 |

|

SPECIAL FOAM SIZES AND CUTS -

If you have a need for a custom cut foam piece, please contact

your salesperson. In most cases, your custom orders can be

completed in one to three working days.

|

|

WARNING: URETHANE FOAM IS FLAMMABLE! -

Do not expose urethane foam to open flames or any other direct or

indirect high temperature source or burning

operation such as welding, burning cigarette, space heater, or naked

flame. Once ignited, urethane foam burns rapidly, releasing

intense heat and consuming oxygen at a high rate. Hazardous gases released by burning foam in an enclosed space can be incapacitating or fatal to a human being if

inhaled in sufficient quantities. The resulting deficiency of oxygen presents a danger of suffocation to the occupant.

No one component by itself passes CAL 133.

|

Randy Cook had to repair his cushions so incorporated an ingenious idea.

Don't be afraid to customize yours. Nothing wrong with being a bit patriotic.

(Points awarded to those who can figure out which state these cushions represent).

The company that made the original cushions for the west

coast SJ23 plant are located at:

Commercial Fabrics Inc.

8702 Aurora Ave. North

Seattle, WA 98103

1(206) 525-0670 Another excellent supplier of cushion foam with lots of "how to" techniques on their website is Sailrite. __________________________________________

V-BERTH FILLER - The factory plywood filler that supports the forward berth cushion

over the head

is (23 3/4 x 36 1/8)" and the fibreglass detent is ~3/8" deep. It would be OK to use thicker 1/2" plywood for strength to rest in the detent as the cushions will simply bend over it. Round off the corners to a

3/4" radius and the edges with a 1/4" radius router. Sand all six

sides smooth

and coat with your favourite finish. Slip it under the forward cushions

while under way so it is handy when you go beddy-bye. However, Buddy has created an alternative to that annoying large plywood board. Read on. "I hated the factory plywood filler because it was so large that the only place it could be stored was under the V-berth cushions. Problem was, it blocked access to the storage area below the V-berth. Since I have water jugs and a seacock there, I had to move that filler board two or three times whenever the boat left the dock. So I threw it in the dumpster and made a foldable, slat style assembly that can be stowed below the V-berth. It's plenty strong and the best part is that I made it from stuff I had laying around the shop." Buddy Wright.

Construction - Spruce or pine planks ~3" wide and 1/2" thick will do the job nicely. Clear coat the wood then staple zig zag nylon webbing to the planks such that the assembly can be folded in a stack. If you need to see this technique first hand, go to the bedding department of an IKEA store. Two Velcro straps around the folded stack keep it in a neat bundle for handling and storage. Buddy's design is brilliant and I foresee many people copying it, including yours truly.

|

If you do this upgrade well, your boat will appreciate it and your friends will be in awe as they board.

If you do this upgrade well, your boat will appreciate it and your friends will be in awe as they board.