| SJ23 Tech Tip H06, (Issued 1999-03-03) Bob Schimmel | |||||||||||||||||||||||||||||

|

San Juan 23 Operating Manual. |

|||||||||||||||||||||||||||||

| NOTE:

This is a copy of the 1977 SJ23 operating manual intended

for online use. I've added many bookmarks to make it easier &

quicker to find things. It

was created through the collaborated efforts of Art Brown and myself

and is reproduced here for your convenience.

There are lots of grammatical and spelling errors in the original manual, there being no word processing in those days and proof reading was expensive. After all, Clark was interested in manufacturing a fast boat, not printing a manual. You should be able to work your way through the grammar but the reading is difficult in some places. I've corrected the errors in this html version so don't print it expecting it to be a copy of the original. The original SJ23 manual was printed on a (5x6)" soft cover booklet. This html version is formatted for (8.5x11)" paper and the page breaks are automatically generated so don't they don't match the page references listed in the text. If you would like a copy of the original text, grammar, punctuation and pictures, composed in MS Word, please email Bob Schimmel. Enjoy. Art Brown & Bob Schimmel. |

|||||||||||||||||||||||||||||

| Congratulations on your purchase of the San Juan 23. Built by

cruising and racing sailors, the San Juan 23 is of the same high quality as

all Clark boats. With a minimum of maintenance, your San Juan 23 will

provide years of sailing pleasure. This booklet is designed to give the new

owner useful information about rigging and maintaining his new boat.

IMPORTANT: To prevent trailer damage to the hull, trailer boat only with normal gear stowed inside to prevent excessive weight on the trailer bunk supports. When loading your San Juan 23, be sure all gear is stowed properly to avoid damage by shifting. A. TRAILER HITCH WEIGHT The weight at the tongue of the trailer should be 150-200 lbs. for proper balance and steering. Major adjustments should not be necessary. B. CHECK LIST BEFORE TRAILING

NOTE:

DRIVE CAREFULLY A car pulling a boat trailer has its mobility, and its ability to avoid an accident, seriously reduced. The principals of defensive driving, which are always important, become critical when you are pulling a boat trailer. Total weight of boat and trailer, normal gear, is approximately 4000 lbs. ------- INDEX ------- Before launching, park on level spot to rig your San Juan 23. Also, check to see there are no overhanging wires between you and the launch ramp. Clearance required after stepping the mast is approximately 36'. The clearance required in the water is approximately 32'.

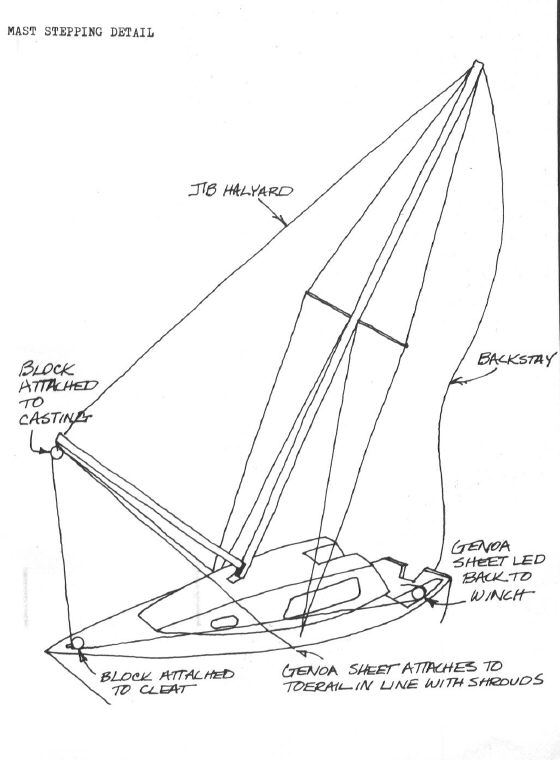

All measurements with turnbuckles 3/4 open, all wire 1x19, 1/8" SS. ------- INDEX -------

Note: Step 7 can be avoided by physically fit adults if one person walks the mast up like a ladder while another person assists by standing on the foredeck and pulling on the forestay. ------- INDEX -------

------- INDEX -------

------- INDEX -------

------- INDEX ------- All fittings are stainless steel, aluminum or plastic. All good quality stainless has a slight amount of carbon steel in the alloy, therefore, you may notice a slight rust film occasionally. This will clean up with soap and water and occasionally a mild abrasive soap such as Ajax or Comet can be employed. A good boat wash after salt water sailing will help keep your fittings looking like new. Oxalic acid, purchased at a pharmacy and diluted in water will remove a rust stain and makes a good teak stripper, but be careful. Wear gloves and flush very thoroughly with fresh water. ------- INDEX ------- The winches are of the highest quality but may become stiff with use due to the ingress of dirt and salt. To clean, carefully remove the drum, flush with fresh water and lubricate with white grease. The pawls can be lubricated with a drop of automatic transmission fluid. ------- INDEX ------- Although your San Juan 23 fiberglass surfaces are maintenance free a little care is needed to keep the boat in like new condition. Frequent washings with soap and water will keep abrasive dirt and salt off the hull and deck (which helps also to keep sails clean). A good paste wax applied at least twice a year will preserve the gloss and help prevent oxidation. Remember strong detergents and abrasive cleaners remove wax so be sure to re-wax after their use. Do not use waxes on the non-skid surfaces. ------- INDEX ------- Follow these step by step instructions to a successful repair of your fiberglass boat. DEEP SCRATCH

LIGHT SCRATCH Merely sand lightly with 600 grit wet and rub with rubbing compound. HELPFUL HINT Wax paper over a fresh patch helps level it until set. Shine will improve with waxing.

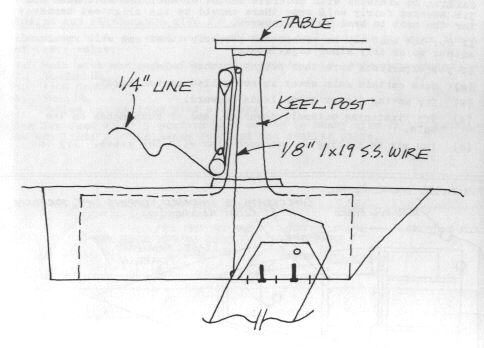

An outboard tank may be used in the port cockpit locker, however, this locker must be vented in accordance with regulations per Motorboat Act of 1940. ------- INDEX ------- A 40 amp hour 12 volt battery in a plastic case is recommended. Obtain wing nut post connectors if possible and strap the battery securely to the inboard face of the aft settee compartment on the starboard side. ------- INDEX ------- The mast and boom of your San Juan 23 are anodized to give the aluminum protection from salt spray and natural elements. It is good to tie all halyards and shrouds away from the mast while trailering and mooring to prevent chafing the anodized finish. Washing with a water hose after sailing in salt water is a good practice. A clean mast and rigging help keep sails clean so wipe road dirt, etc, off before stepping the mast. ------- INDEX ------- Standing rigging should be inspected periodically for broken strands or loose bolts and clevis. Also check turnbuckle barrel lock nuts for tightness. Keep the spreader tips well taped to prevent damage to the sails. Running rigging may become stiff with dirt and salt after use. This can be remedied by washing in light detergent or flushing with a garden hose. Always tie a figure eight knot in the ends of the main and Genoa sheets to prevent them from coming out of the blocks or fairleads. Never tie a knot in the end of the spinnaker sheets. ------- INDEX ------- The keel centerboard is designed to give maintenance free operation, however, the boat should [be] hoisted yearly and the trunk cleaned of marine growth, and the lifting wire inspected. Replace the wire if any broken strands are found. The pin for the centerboard is movable fore and aft. It is installed in the middle position, however, [it] may be moved [forward] if more weather helm is desired and aft if a more leeward helm is desired. The centerboard pin is on a "stirrup" which is lag bolted to the bottom of the keel. Ensure that the lag bolts are put in with polysulfide (Boat Life) caulking compound.

------- INDEX ------- Many sailors prefer to leave their teakwood "bleach" and thus do nothing for maintenance. To preserve the oiled finish, however, it is necessary to re-oil the teak with a good teak oil such at Watco or Tung oil whenever it becomes noticeably weathered. ------- INDEX ------- The cushions are fabric Scotchguard and may be cleaned with a damp cloth. Care must be taken to prevent mildew by turning cushions upright when leaving the boat. When boat is out of use for a longer period of time, remove the cushions and store in a dry place. ------- INDEX ------- Always remove the battens, fold carefully, bag and store sails in a dry location. Never fold wet sails, but wait until dry to prevent possible mildew. Dacron sails can be rinsed free of salt with fresh water, then laid on the grass and rinsed with water hose. Never iron sails to remove the wrinkles. ------- INDEX -------

------- INDEX ------- TUNING AND PERFORMANCE TIPS FOR THE SAN JUAN 23 About the best, or most used combination sails, seems to be in the order of their value:

The San Juan 23 will perform much better in heavy airs if she is "sailed on her lines". This means reef and use smaller sails. ------- INDEX ------- MAINSAIL - The mainsail will usually be built out of 5.2 oz. Dacron specially woven for mainsails. All mains will come standard with one row of reefs, shelf foot and Cunningham hole. An additional row of reef points is recommended for areas with winds exceeding 30 knots. 150% GENOA - 199 sq. ft. - The 150% genoa is designed to be the largest headsail carried on the San Juan 23. It is usually built out of 3.8 Dacron and is principally used in winds up to 12 knots. 115% GENOA - 120 sq. ft. - This sail is cut low on the hoist and designed for winds from 10 to 20 knots. It will usually be built out of 5.5 oz. Dacron. WORKING JIB - 80 sq. ft. - The working jib is a sail that will allow the boat to be driven easily in strong airs with excellent balance and control. RADIAL HEAD SPINNAKER - This is an all purpose spinnaker with a radial head and horizontal lower panels. It is made of .75 oz. nylon. The spinnaker is cut with an elliptical shape to give it maximum projected area on a run and good reaching capabilities. Following is a chart for use in sail selection. Try it and let us know your successes and/or failures and we'll try to keep it updated.

------- INDEX ------- |

|||||||||||||||||||||||||||||

SAN JUAN 23 ORIGINAL SPECIFICATIONS FOR RACING...As printed in Clark Boat Company SJ23 Owners Manual - 1979 Edition

Measurement Rules It is the intent of the Measurement Rules of the class to insure that boats race and remain as nearly identical as possible within normal building tolerances and to insure and enforce the One Design nature of the Class. Accordingly, any equipment or modifications to equipment deemed by the class to contravene either the spirit or the letter of these rules shall be outlawed.

Article I - General The selection of original fittings, spars, sails and any other equipment furnished with a San Juan 23 sloop at the time of its sale by the manufacturer shall be within the discretion of the Clark Boat Company.

Article II - Hull Construction

Article III - Mast and Boom

Article IV - Rigging and Equipment

Article V - Sails 1 General

2 Mainsail

3. Jib sail (working)

4. 115% Genoa

5. 150% Genoa

6. Spinnaker

________________________________________________________________________________________________ "It is my intent to suggest to the association just forming that we set up

a Rules Committee or act as a committee of the whole to review the above

Measurement Rules of the class as originally promulgated with the purpose of

approving reasonable deviations in equipment or modifications to equipment

for the purpose of maintaining racing competition in the class while at the

same time being reasonable in light of the fact the San Juan 23 is no longer

in production. It would seem some handicap could be assessed for

modified equipment that provides a clear advantage in racing without

outlawing that equipment just because it contravenes either the spirit

or the letter of these original rules."

Chuck Van de Wetering |

|||||||||||||||||||||||||||||

|

SAN JUAN 23 ONE DESIGN ASSOCIATION CONSTITUTION (Since the SJ23 One Design Association no longer exists, this section

of the manual is purposely left out for this version of the manual. It may be added at a

later time.) |

|||||||||||||||||||||||||||||

|

Return to Tech Tip Index. . . . . . . . . . . . . . . Have a Question? |

|||||||||||||||||||||||||||||

Rigging lengths:

Rigging lengths: