|

FLAT

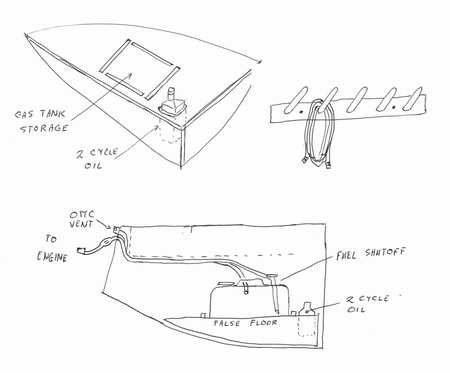

FLOOR - The

false floor in Panache's port locker is constructed of 3/4" plywood with vertical supports (1x8)" of solid spruce planks shaped to fit the hull form along with a UHMW

foot at the corner.

It requires a bit of "art work" to draw the

floor line along the curved hull side of

the locker. To make this job easier,

draw a fore/aft line at the height of the false floor, parallel to the cockpit sole. Continue the line from the corner out to the hull along the bulkhead side of the locker. Finally join the

ends by drawing the line along the hull using a projected laser line.

To

make it easier to draw the line, position

the laser on a temporary flat surface in the corner of the locker with the

edges parallel to the lines drawn. Project the laser line to the ends of lines previously drawn. Draw your line on the hull along the laser line.

Don't have a laser? Fill the locker with water to the desired depth and draw your lines just above the surface! Probably

a lot easier and you get a chance to check the water tightness

of the locker, plus clean it! Finally, use cardboard to

make a pattern so you don't waste your last piece of plywood. If you

want this assembly to last forever, saturate the wood in epoxy and use

some UHMW for the foot (at the corner) so the wood stays

high and dry. Water will eventually accumulate to this low spot from various

leaks. If there is water in the "sugar scoop" aft of the cockpit,

it came from

the gudgeons, transom chain plate or cockpit drain fittings.

If the "sugar scoop" is dry the water came from the

scupper, locker lid hinges, gunwale fittings or condensation. To

make it easier to draw the line, position

the laser on a temporary flat surface in the corner of the locker with the

edges parallel to the lines drawn. Project the laser line to the ends of lines previously drawn. Draw your line on the hull along the laser line.

Don't have a laser? Fill the locker with water to the desired depth and draw your lines just above the surface! Probably

a lot easier and you get a chance to check the water tightness

of the locker, plus clean it! Finally, use cardboard to

make a pattern so you don't waste your last piece of plywood. If you

want this assembly to last forever, saturate the wood in epoxy and use

some UHMW for the foot (at the corner) so the wood stays

high and dry. Water will eventually accumulate to this low spot from various

leaks. If there is water in the "sugar scoop" aft of the cockpit,

it came from

the gudgeons, transom chain plate or cockpit drain fittings.

If the "sugar scoop" is dry the water came from the

scupper, locker lid hinges, gunwale fittings or condensation.

To

clean the bottom of the locker or remove the water, just slide the

shelf aft to expose the bottom. Then you can use a large sponge

(if you have long arms to reach the bottom) or a pump to empty it.

This spot should be the first place to install an electric

bilge pump on an SJ23. See Tech Tip C12.

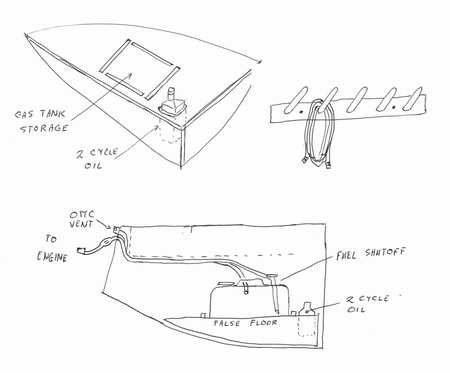

GAS TANK -

One of the biggest advantages

of a flat floor is to keep the gas tank high and dry plus level, so you can burn

ALL the fuel for maximum operating range. Now you no longer get those

odd comments from the dock watchers as you hold

the tank level inside the locker while you tickle the tiller with your

toes to motor that last little bit to the gas dock! Just

think, you can actually have an accurate reading on the fuel gauge.

What a novel thought! Drill a couple

of 2" holes through the shelf, under the tank, to keep the bottom of the tank

ventilated (dry). It helps to prevents rust.

To prevent the gas tank from sliding screw four fiddles (strips of wood from an old hockey stick) around

the base of the tank. Hockey stick

handles are a renewable resource of excellent hardwood in

Canada!

If you sail heeled over more than 300

strap the tank to the shelf to keep it inside the fiddles. Although

in practice, I've found that the low profile 2.5 gal Merc tank does not

move. It's still a good idea to strap it down. A taller

5 GAS TANK -

One of the biggest advantages

of a flat floor is to keep the gas tank high and dry plus level, so you can burn

ALL the fuel for maximum operating range. Now you no longer get those

odd comments from the dock watchers as you hold

the tank level inside the locker while you tickle the tiller with your

toes to motor that last little bit to the gas dock! Just

think, you can actually have an accurate reading on the fuel gauge.

What a novel thought! Drill a couple

of 2" holes through the shelf, under the tank, to keep the bottom of the tank

ventilated (dry). It helps to prevents rust.

To prevent the gas tank from sliding screw four fiddles (strips of wood from an old hockey stick) around

the base of the tank. Hockey stick

handles are a renewable resource of excellent hardwood in

Canada!

If you sail heeled over more than 300

strap the tank to the shelf to keep it inside the fiddles. Although

in practice, I've found that the low profile 2.5 gal Merc tank does not

move. It's still a good idea to strap it down. A taller

5

gallon tank might tip

so strap it down. For convenience, I drilled a hole in the false

floor to hold a vinyl bottle of 2 cycle oil and installed a

stub of

wood on top of the shelf to

support an inverted funnel.

The gas tank shown is a Mercury 2.5 US gallon tank. The floor is big

enough to support a 5 Imp gallon tank. gallon tank might tip

so strap it down. For convenience, I drilled a hole in the false

floor to hold a vinyl bottle of 2 cycle oil and installed a

stub of

wood on top of the shelf to

support an inverted funnel.

The gas tank shown is a Mercury 2.5 US gallon tank. The floor is big

enough to support a 5 Imp gallon tank.

LINE

STORAGE

RACK -

Line is only useful if you can get at it and if it is ready to use. You always need

it for docking, to replace a sheet or to dry

your "unmentionables" in the wind. Line dumped in the bottom of a locker will

always soak up water and snarl up so it is miserable to use.

I hate line that stinks! Line coiled on a

rack is easy to find, ready to use and dry. I built the storage rack

shown above to bolt against the forward end of the port locker. The

rack is made of 6" long 3/4" dowels drilled and glued into a (3x4)" plank.

It is

very convenient to use, requiring only one hand, and a wet line dries nicely without smelling up

the cabin. A coiled line has never dropped from a peg.

|

To

make it easier to draw the line, position

the laser on a temporary flat surface in the corner of the locker with the

edges parallel to the lines drawn. Project the laser line to the ends of lines previously drawn. Draw your line on the hull along the laser line.

To

make it easier to draw the line, position

the laser on a temporary flat surface in the corner of the locker with the

edges parallel to the lines drawn. Project the laser line to the ends of lines previously drawn. Draw your line on the hull along the laser line.