| SJ23 Tech Tip B09, (Updated 2024-02-06) Bob Schimmel | |||||||||||

|

Rudder Repair and Dimensions. INDEX - Rudder Head, Rudder Shell, Replace a Pintle, Transporting a Rudder, Leaking Gudgeon, Propeller Damage, Wet Core Repair. |

|||||||||||

There

are many ways you can loose the rudder or damage the blade. Below are some popular ones. Take your pick!

Once you understand this problem it should not come as a surprise! The best way to solve it is to install an epoxy compression sleeve inside each bolt hole as depicted by the green epoxy in the kick-up rudder drawing at right. KICK-UP RUDDER PIVOT HOLE - The sketch at right shows a cross profile of the kick-up rudder head equipped with an epoxy compression sleeve bonded inside the blade (green) and a bronze bushing (brown) inserted to keep the plates of the rudder head apart. The gap shown between the blade and the rudder head is exaggerated. In reality the gap is barely there, to eliminate steering slop. The tiny gap is maintained by the slight protrusion of the bronze sleeve. This gap is about 1/16" and ensures easy pivoting, minimal side play and no compression of the blade shell.

Find a 1/2" ID bronze bushing with a (minimum) 1/8" wall thickness that

fits snug over the pivot

bolt. A thick wall bushing is better than a thin wall. Bushings are available from a

bearing supply house. Ream out the hole in the blade so the bushing just

slides through. Dry fit the bushing to confirm that it aligns with the rudder

head and there is free pivot movement of the blade. Then form an epoxy compression sleeve inside the rudder blade by using a Dremel

tool (or similar) to gouge out 1/4" of foam from inside the pivot bolt

hole. Replace the gouged out foam with epoxy thickened with carbon graphite powder

(peanut butter consistency), effectively forming a tube of

slippery epoxy that bonds both

shells together. This is your epoxy compression sleeve that also

seals the foam core. It is OK to slightly overfill the hole. Smooth and form the inside of the

wet epoxy by inserting the bushing. If you lightly coat the bushing with some wax, release agent or cooking

oil it can't stick to the epoxy. Let cure for 24 hours. Once cured, remove the bushing and cut the length to about

1/16" longer than the

thickness of the blade. FIXED RUDDER PINTLE MOUNT - Similar to above, if you have a fixed rudder, install an epoxy a compression sleeve through the rudder at each pintle mounting bolt. This prevents crushing the rudder and seals the rudder shell to keep water out. It adds a tremendous amount of form strength which is very important on the fixed rudder. Use a Dremel tool to gouge out 1/4" of foam from inside each bolt hole. Replace the gouged out foam with thickened epoxy (peanut butter consistency), effectively forming a tube of epoxy that bonds the shells together. It is OK to slightly overfill the hole a bit. Smooth and form the inside of the wet epoxy by inserting the bolt. If you lightly coat the bolt with some wax, release agent or cooking oil it can't stick to the epoxy. Let cure for 24 hours. The epoxy sleeves guarantee you won't be able to crush the shells together. Install a similar sleeve for the tiller bolt. top

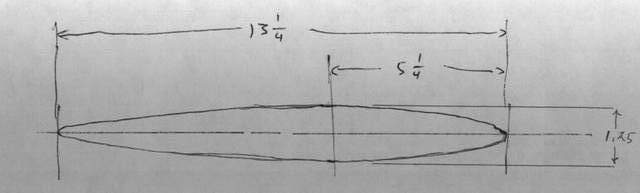

The dimensions are shown in inches. The sketches are NOT to scale but they are fairly accurate. The dimensions for the fixed rudder, are the same as the overall dimensions of the kick up rudder.

If you don't have the ambition to rebuild a broken blade or build a new rudder, then San Juan Sailboats (Stephen Jensen) makes a replacement rudder that has a thicker shell with lighter foam. I told he will guarantee them for at least two years. Send your order to.

The sketch below is a close approximate of the cross profile of the blade. It's very difficult to copy a full size blade in this dimension.

REPLACE A PINTLE - If you loose a pintle from its mounting strap, it can be replaced with a 3/8" stainless steel bolt or rod. Choose a bolt that has at least 3" of unthreaded shank. Grind the threaded end of the bolt to a slight taper to aid inserting it into the gudgeon. Cut the bolt to 3" long. Make the bottom pintle at least 1" longer than the top one to aid in installing the rudder on the transom. You'll appreciate this once you are on the water. Drill a 1/8" hole through the side of the pintle mounting strap and the bolt. Insert a 1/8" bolt and nut or a roll pin through both to lock the new pintle in place. Use a liberal amount of sealant between the pintle and the strap to lock the bolt in place and minimize movement. You don't want a sloppy fit. While you're at it, drill a 1/8" hole across the end of the pintle (just below the gudgeon) so you can use a hair pin or cotter pin to lock the rudder to the gudgeon. That silly little factory stainless steel retaining spring on the gudgeon is a joke. The slightest bump against the rudder and the spring lets go. So install a heavy duty hair pin. top

TRANSPORT

A RUDDER - A rudder isn't exactly light, the shape is awkward

and the surface is slippery when it comes out of the water, which doesn't lend itself to easy storage. However, if you make a couple of wood

support brackets (show at right) the rudder can lie on the cabin floor where it

will stay put. It never rubs against the cabin wall when

traveling down the highway and is perfect for winter storage. PROTECT A RUDDER FROM PROPELLER DAMAGE - Propeller gouges in the blade should be tended to immediately before water can soak into the foam core. This is another one of those good reasons for carrying a roll of duct tape on the boat. This tape will stay attached underwater provided it is applied to a dry surface so you can at least get home without fear of the foam core saturating with water. Once you arrive, use the standard techniques of cloth and epoxy covered with gel coat to do a permanent repair. Duct tape (mach III tape in the US and Mach IV tape in Russia!) doesn't last forever, despite what some people will tell you! There are several techniques to protect the rudder blade from touching the propeller:

And that's about it for the rudder. |

|||||||||||

FACTORY CONSTRUCTION - I'm hoping that the small parts tooling is still around in Gene's back yard or in western Washington somewhere. The days get foggy with age or too many styrene fumes coming from the Clark laminating shop. If the tooling is still around, I could draw up the lamination schedule for a rudder and a real part could be built. Gleno.

|

|||||||||||

|

DIY RUDDER WET CORE REPAIR - Replace wet core in a spade rudder. Excellent technique that can be done by a capable DIY person. Epoxyworks back issues. |

|||||||||||

|

BUY A RUDDER - This off the shelf kick up rudder may be pricy but is expedient. The blade is larger than the factory version that can hold the boat from rounding up when over powered. I like the way the blade can fold up to vertical. You might actually be able to tow it down the road with the rudder on the transom. https://store.ruddercraft.com/index.php?route=product/product&path=182_62&product_id=862 |

|||||||||||

|

Return to Tech Tip Index. . . . . . . . . . . . . . . Have a Question? |

|||||||||||