Panache

has undergone many modifications to make life more comfortable

in the cockpit and safer on deck. The most challenging and rewarding was the conversion of the corner stanchions to a pushpit in 1998. Here's why: Panache

has undergone many modifications to make life more comfortable

in the cockpit and safer on deck. The most challenging and rewarding was the conversion of the corner stanchions to a pushpit in 1998. Here's why:

- I always considered the factory

cockpit

corner stanchions lethal if I were to fall on one. For this reason alone the design would never be accepted in industry today and was my primary motivation to fabricate a pushpit.

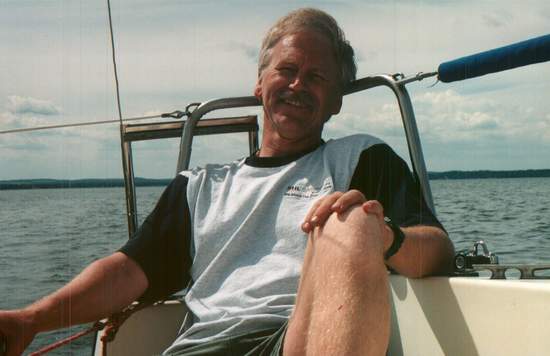

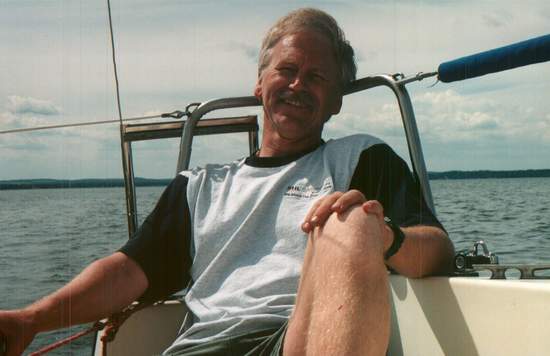

- The post is also uncomfortable to lean against. You can see Carey resting against a corner post with his spine to one side of the post. You

learn this trick pretty quickly when the pain tells you to move sideways! While this is not the most comfortable

position in the

world, it is better than nothing. Slipping off the critical position can hurt

the vertebrae which is

another reason why I

decided to get rid of the corner stanchions.

- My third reason for building the pushpit is to create lifeline gates. This way I

don't have to do a potential life altering pirouette over the life line to step on/off the dock.

- This conversion also eliminates the hassle of having to latch the pelican hook in mid air. I always found this difficult when I had to pull the lines around the corner stanchions with netting tied to the toe rail at the bow.

- I consider it the height of luxury to sit on the low side of the cockpit at hull speed, wedged in the corner against the cabin wall with my legs stretched along the bunk. Inevitably my head ends up resting against the cabin so my head is as one with the motion of the hull while staring at the wake. The view over the transom is mesmerizing, especially with a

setting sun.

Unfortunately, it is "somewhat difficult" to see forward from

this position. Since I sail solo a lot I built this pushpit so I can

be just as comfortable facing forward. What a novel thought!

PUSHPIT

DESIGN

CRITERIA

(1998)

- I

think a SS pushpit is one of those things where art follows function. I designed this pushpit to be proportional to the hull and

parallel to the major hull lines so it looks good.

It has to be pleasing to the eye, comfortable to lean

against,

functional and extremely strong so a person can stand or sit on it. I

tend to do the odd acrobatic stunt while onboard!

Don't ask. To fit this criteria I decided on a split pushpit with a transom gate made of SS lifeline closed with a pelican hook. A one piece pushpit is actually easier to make. A split

pushpit creates

relatively easy access to the

outboard, has easy boarding from the transom ladder, has rounded edges for

safety and leaves room for a future

split backstay tension adjuster. PUSHPIT

DESIGN

CRITERIA

(1998)

- I

think a SS pushpit is one of those things where art follows function. I designed this pushpit to be proportional to the hull and

parallel to the major hull lines so it looks good.

It has to be pleasing to the eye, comfortable to lean

against,

functional and extremely strong so a person can stand or sit on it. I

tend to do the odd acrobatic stunt while onboard!

Don't ask. To fit this criteria I decided on a split pushpit with a transom gate made of SS lifeline closed with a pelican hook. A one piece pushpit is actually easier to make. A split

pushpit creates

relatively easy access to the

outboard, has easy boarding from the transom ladder, has rounded edges for

safety and leaves room for a future

split backstay tension adjuster.

NOTE -

While I like a pushpit corner seat like those on a wide transom boat these

days, I rejected them for an SJ23

due to the narrow stern. There just isn't enough

buoyancy to carry four adults in the cockpit, let alone a crew sitting on the

pushpit. I realize it may afford a grand view

but it will raise your head above the bottom of the jib, defeating the purpose of sitting that high.

You really should stay within the safety of the cockpit when sailing

solo, which means keeping your feet on the cockpit sole. I wouldn't necessarily discourage a person from

installing a seat, just remember to manage your expectations.

The following

guidelines are

specific to the design with the water line horizontal:

-

SS TUBING -

Use 1" OD (25 MM) stainless steel ornamental tubing to match

the pulpit. Ornamental tubing is well within the strength

requirements and the thinner walls bend relatively easy, making it

possible to create a kink free 3" radius bend. A 3" radius bend

fits

perfectly around my head as shown below, making a very

comfortable rest.

NOTE - It is very difficult to describe in XYZ terms the

dimensions and angles of this pushpit since it rests on a curved

surface. This is more about art than structural engineering! For the purpose of this description the horizontal sections

of the pushpit are called rails and the vertical sections are

called legs.

-

TOP

RAIL - The top rail, to the right of my head, is parallel to the top of the

transom. TOP

RAIL - The top rail, to the right of my head, is parallel to the top of the

transom.

- The top rail to the left of my head is parallel to the toe rail.

The tops of both rails are 17.5" above deck. This is

slightly higher than the height of the lifelines (16.5") so the pelican hooks

can latch just below the top. This way the

life line forms a gentle curve, parallel to the toe rail. The

lifeline attachment ring leaves no sharp projections.

- When

bending the stainless tube ensure that port and starboard

upper rails have a symmetrical spread of 1030 each.

I found this to be a painstaking job given the compound angles.

-

LOW RAIL -

The lower horizontal

rail is

parallel to the upper rail and

9" above deck, making it very comfortable to lean on or against. While

not totally required it sure adds comfort. Now we're getting

somewhere.

-

AFT INSIDE LEG

- The angle of the aft inside leg (behind my right shoulder) parallels the

side of

the companionway, about 130 off vertical. Or you

could parallel the slope of the tiller cut out which is

easier to copy. Your choice. The two are almost parallel. The fore/aft angle is about 100 aft

with the boat floating. The horizontal angle

between the rails is 1030.

-

MID LEG - The angle of the

middle leg is about

100 aft

with the boat floating.

It can easily support the weight of a person standing on it or leaning

against it. The location of this post creates minimal

restriction to access the outboard.

-

FORWARD LEG - The

fore/aft angle of the forward leg, behind my left shoulder, is

1050. The sideways angle follows the

curvature of the

hull.

Cut

all legs over length by a few inches. This gives you the extra

material to fit the pushpit at precisely the correct height and angle to the deck. This is

real painstaking work so take your time.

It is easy to build the first pushpit "perfect," but real difficult to

build a second pushpit that is a perfect mirror image. For this

reason, fit the side with the shorter legs first. Long legs can always

be cut shorter, but short legs, never!

-

FEET - Make

the

feet from 1/8" thick stainless steel flat bar, (1x2)", welded to the bottom of each

post so it is parallel to the deck for secure bolting. Each foot has three 1/4" holes drilled it.

A 1/4" holes through

each end to bolt to

the deck or through the toe rail and one immediately under each tube to

relieve the internal air pressure for welding. It can be left open

as a vent

hole or to run electrical wiring through if you wish. I sealed mine with

goop.

Later

I may run wires through it for navigation lights.

-

SEALANT -

Use plenty of Sikaflex marine sealant or butyl rubber under each foot

and under the bolt heads or the cockpit lockers will slowly fill with

water. Use 2" long

bolts to facilitate assembly with nylock nuts and the biggest

fitting washers you can find. The washers will help to retain sealant as you tighten the

bolts.

FINAL FIT

- When you look

over the pushpit (across the cockpit) the port and starboard rails and

legs MUST be parallel to each other. (This step is very important

because the dock watchers will scrutinize your workmanship).

- The

tubing may be polished

to match the pulpit but I doubt you can match the shine of the

factory finish. I'm quite sure the factory finish is

chemically polished because that process produces a chrome like

finish.

The welding is sure nice. The other polishing technique is to

buff the metal with lapping cloth which could be quite an ordeal, given all the curved

surfaces. Polishing will improve the

resistance to corrosion by removing the microscopic fissures that trap

debris. I think polishing would be easier with the units still

off the boat.

TOOLS

- It

is a tricky task to fabricate two symmetrical units and

then mount them on a curved deck so they are parallel to each other, the

deck surfaces and the cabin lines. One screw

up

in the mounting stage and all your perfect bends during fabrication go

down the drain. It think I can quite safely say that I

measured ten times for each bend or cut, maybe more. There are three

tools I found to be very handy.

-

A pointer stick that can be temporarily clamped at any angle to the

tubing to simulate a mid rail or leg. This

is a very quick and accurate reference guide to aid in positioning

tubing at the correct place and angle. I don't know of a

commercial made tool so I made one from a hose clamp tightened over a piece of

bent flat iron. A mitre bevel can work well but it doesn't stay in

place.

-

A fine point "Sharpie" to mark the tubing. The ink washes off

SS easily with acetone.

Writing on masking tape works well too but remember to wash off the

adhesive before welding. A pencil is useless. Several years after this job my son showed me a Sharpie

designed for stainless steel. Sure wish I knew about this back

then.

- Another handy tool that I

currently own but didn't know about at the time, is a Unitek

Magnetic POLYCAST Protractor. It measures angle in degrees

relative to the center of this planet (gravity), similar to an inclinometer. (Its used to set the angle of elevation for a satellite dish). The ~10 accuracy is very

useful for transferring angles from port to starboard to measure

symmetry, provided the boat is absolutely level.

CONSTRUCTION

- Bending SS

tubing must be done with a bender designed specifically for the

properties of SS. It pulls the tubing around the mandrill,

instead of squeezing it around the corner that is the technique used for

bending conduit. SS benders are almost always power

assisted or have a long lever for mechanical advantage. It takes a lot of force to bend SS tubing. The one I used was mounted on a waist high work bench and came

with a 6' long lever. Ridgid

makes a geared ratchet portable tube bender that just might work for

you. I have no

experience with this tool but it looks promising. Keep in mind

that the bending radius is set by the diameter of the mandrill and the

inside of the mandrill must

match the diameter of the tubing. It takes skill and a lot of setup time to produce good results. CONSTRUCTION

- Bending SS

tubing must be done with a bender designed specifically for the

properties of SS. It pulls the tubing around the mandrill,

instead of squeezing it around the corner that is the technique used for

bending conduit. SS benders are almost always power

assisted or have a long lever for mechanical advantage. It takes a lot of force to bend SS tubing. The one I used was mounted on a waist high work bench and came

with a 6' long lever. Ridgid

makes a geared ratchet portable tube bender that just might work for

you. I have no

experience with this tool but it looks promising. Keep in mind

that the bending radius is set by the diameter of the mandrill and the

inside of the mandrill must

match the diameter of the tubing. It takes skill and a lot of setup time to produce good results.

Most of the SS tubing I've seen has a longitudinal line on the outside. I think this is a result of the manufacturing process. If your tubing doesn't have a reference line, draw one with a "Sharpie" (felt pen). Use the line to assist you for marking a reference. The line can be used to determine the start and finish of a bend and the correct axis of the bend. Without it, you will be spending tons of time orienting the tubing with each bend, which is very frustrating to say the least. You will be doing lots of double checking anyway and this reference line sure makes the job

easier. The line also helps to keep you oriented to the tubing as it is all too

easy to confuse port for starboard, fore for aft and up for down. Another slick trick is

to mark each unit with tape for port/starboard and fore/aft

reference. I learned all this on my second unit which I bent in one third

the time of the first unit.

FITTING to the DECK

-

Unfortunately I miss placed my plans. I built

the pushpit before I ever

decided to publish these Tech Tips. They were written on

restaurant napkins and scraps of paper. As I recall, I started fitting each

corner assembly to the

transom first, then worked my way forward. I adjusted the

position and angle of the first assembly till it was parallel to the companionway

opening and the cockpit lines. Then I adjusted the position and angle of the second

assembly till it was parallel to the companionway, cockpit lines, and

being symmetrical to the first unit. A tricky business to say the

least. You might have to juggle both assemblies a bit to make a happy

compromise for symmetry. Symmetry and parallel is very important

though.

It might help to attach both units to a straight plank placed across the top

to lower the assemblies on the deck. While the

exact lengths of the legs were marked with masking tape, I

cut each 1" longer than required just to be safe. I placed them

on the deck to determine if there were any inaccuracies. I

used this technique to incrementally cut each assembly to the correct deck

height so they were symmetrical. A very painstaking, tedious process. If I were to fabricate

them again I would make plywood moulds to form the tubing

around and attach two posts to the toe rails to run alignment strings

across the cockpit. This would give me a reference line elevated from the deck

surface without the need to constantly measure with a tape.

Having figured out the dimensions at home I did all the tube bending at

a shop where a friend loaned me the use of their bender. Coffee

for the guys was cheap! In the absence of a mould the feet

were welded in place with Panache backed into a welding shop. It was raining at the time and no welder will stand in a puddle of water

while the stick is lit! So I just backed her in through the overhead door. To say that my project captured the

interest of the entire shop is the understatement of the year. Fact is,

with Panache in the shop they couldn't do anything else anyway and with this

many "experts" running around you just can't go wrong.

Two guys holding SS in place while the welder tacks it is not

to be discounted. I was directing the show and ordered

coffee, again! Once I got the two pushpits home I hammered the feet slightly

till they fit flush to the deck. As a weld cools it has a

tendency to shrink and pull metal away from the original position.

Afterwards I ground each weld smooth and polished the metal.

You should be able to reverse engineer this pushpit from the

photos and the description here. If you would like more detail pictures, just email

me quoting this Tech Tip.

CONCLUSION

- After sailing

several years with the split pushpit I can report that life on board is easier with increased safety and comfort in the cockpit.

Access

from a dinghy or dock to the cockpit is quicker as it is now a simple

matter to release the pelican hook in front of me. I am still

amused when another SJ23 owner steps on board and is amazed with

how easy it is to open or close a gate. The hazardous corner posts are

replaced with smooth tubing that is strong enough to stand on and

is definitely comfortable to lean against. As a surprise, the

cockpit has become a bit roomier because the lifelines are now slightly further

outboard. I can now sit on the

coaming and rest against the life line for a better view forward. This is definitely one of

those situations where all the little modifications combine to create a significant

improvement for safety, comfort and convenience.

PS: It also looks better than corner posts.

In these photos I have yet to fabricate the life line gates.

Click here to see Liberty Call's

split pushpit, proving that this pushpit can be reverse engineered.

NOTE

- Back

in the days when Clark owned San Juan, a company called

Railmakers Northwest built all the rails, stanchions, etc. They did nice work and

had patterns for the tooling, so pulpits and what-not just bolted on. They are still located on the Everett, Washington waterfront (near the boat

ramp).

_______________________________________________________

LIFELINE

GATE

- I never did like the

way the original lifeline dropped to the deck when the single pelican

hook over the transom was released. Lying free on the deck, the

line was in the way and

I found it a real nuisance to

pull the lifelines taught again, especially since I have netting tied at

the bow. I always thought

the Clark brothers could have done a better job of the lifelines for a boat as classy as an SJ23.

At the time of this project, Panache floated at a mooring

and I found it "difficult" to crawl from my dinghy, over the gunwale,

without getting hung up on a lifeline. It was awkward, to say the least and

quite a balancing act in lumpy water. LIFELINE

GATE

- I never did like the

way the original lifeline dropped to the deck when the single pelican

hook over the transom was released. Lying free on the deck, the

line was in the way and

I found it a real nuisance to

pull the lifelines taught again, especially since I have netting tied at

the bow. I always thought

the Clark brothers could have done a better job of the lifelines for a boat as classy as an SJ23.

At the time of this project, Panache floated at a mooring

and I found it "difficult" to crawl from my dinghy, over the gunwale,

without getting hung up on a lifeline. It was awkward, to say the least and

quite a balancing act in lumpy water.

To

solve the problem I

transformed the aft stanchion (forward end of cockpit, 18" tall, 1" OD) into a lifeline gate by bracing the forward side

with a SS rod angled into the deck. The angle brace

supports the stanchion, relieving the mounting plate of stress when the gate

is open. The gate being the space between the

aft stanchion and the

pushpit. The braces were

welded to the stanchions, something I now regret. While they work

very well, attaching them with

a bracket equipped with set screws would have been so much easier for ongoing

maintenance and winter storage. To terminate the forward life line

and maintain tension I fabricated a stainless fitting (bolt with half

ring welded to the head). The tension

in the forward line is adjusted with a turnbuckle at the pulpit.

The tension of the gate line is adjusted with a

threaded Pelican hook latched to the metal loop welded at

the top of the pushpit. Always close this Pelican hook

facing outward to prevent accidental release by rubbing against it in

the cockpit. I quite often find these hooks closed the opposite

way and reverse them for safety. Its amazing how many sailors are

unaware of this simple act. For comfort and safety, the lifelines

gates are cushioned with foam tubing covered

with Acrilan or Sunbrella cloth as shown below. The tension of the gate line is adjusted with a

threaded Pelican hook latched to the metal loop welded at

the top of the pushpit. Always close this Pelican hook

facing outward to prevent accidental release by rubbing against it in

the cockpit. I quite often find these hooks closed the opposite

way and reverse them for safety. Its amazing how many sailors are

unaware of this simple act. For comfort and safety, the lifelines

gates are cushioned with foam tubing covered

with Acrilan or Sunbrella cloth as shown below.

Lifeline covered in vinyl can be a hazard in the long run due to hidden

corrosion. One day when you need it most, the line lets go.

Not good! So consider replacing them with Dyneema (Tech Tip B37) which is easy to splice. But you still need chafe protection at each stanchion hole in the form of a vinyl tube.

____________________________________

LIFELINE PADDING (1998) - Shortly after installing Panache's pushpit in 1998 I realized that leaning against a life line was not comfortable. So I added foam padding over the lines adjacent to the cockpit; (hollow foam water line insulating tube or a foam noodle covered with blue Sunbrella cloth). You can see one installed here and below. They work very well but with years of body pressure against them, the thinner life line wire eventually wore through the foam, leaving the sharp line against my back again. Aaarch, nothing lasts forever I guess!

(2022) I replaced the foam and this time inserted a vinyl tube inside the hollow foam with the life line run through the vinyl tube. The vinyl tube spreads the load over a wider area to keep the pads comfortable and make them last longer. The vinyl also bends when I lay the line on the deck. I also soaked the Sunbrella in hot water and scrubbed off the Lichens, which shows you how long I've had these pads. Maybe 34 years is forever after all.

With Canada having converted to metric in 1975, the foam insulating tube today is a tad thicker than the previous imperial version which means it fills the Sunbrella tubes fully, resulting in a softer pad. Sometimes change is a good thing.

|

Panache

has undergone many modifications to make life more comfortable

in the cockpit and safer on deck. The most challenging and rewarding was the conversion of the corner stanchions to a pushpit in 1998. Here's why:

Panache

has undergone many modifications to make life more comfortable

in the cockpit and safer on deck. The most challenging and rewarding was the conversion of the corner stanchions to a pushpit in 1998. Here's why:

The tension of the

The tension of the

This split

pushpit shown belongs to Kevin from Kentucky. His design is

simpler and easier to fabricate than Panache's above. It is also easier to bolt in place. The fact that it is removable makes it very useful for winter storage. I like that.

This split

pushpit shown belongs to Kevin from Kentucky. His design is

simpler and easier to fabricate than Panache's above. It is also easier to bolt in place. The fact that it is removable makes it very useful for winter storage. I like that.

"I finally

completed my project using the last of the material in my garage. A local welder tacked it

together at a reasonable price. The polishing and

installation was fairly easy. Polishing compound with a

buffing wheel took most of the burn marks off. Then rubbing the SS with 00 steel wool and Comet cleanser

created the final finish. The pushpit adds a nice touch

to Liberty Call and is very functional. Glad I got it done."

"I finally

completed my project using the last of the material in my garage. A local welder tacked it

together at a reasonable price. The polishing and

installation was fairly easy. Polishing compound with a

buffing wheel took most of the burn marks off. Then rubbing the SS with 00 steel wool and Comet cleanser

created the final finish. The pushpit adds a nice touch

to Liberty Call and is very functional. Glad I got it done."