| SJ23 Tech Tip E12, (2022-07-07) Bob Schimmel. | |

|

Install a Tiller Autopilot -

Lashed Tiller or

Wind Vane. |

|

|

Imagine you are sailing single handed and you have to attend an urgent "meeting" at the head! Wearing your foul weather gear would probably make this a worst case scenario but what are you going to do, considering that you don't have automatic steering and it's pretty difficult to ignore this "meeting"! You could hove to, which is probably the calmest motion to hold a "meeting," no pun intended. There are other less daunting but equally important tasks like adjusting a whisker pole or retrieve that "dear child" you lashed in the pulpit. Then there are those important trips to the galley to maintain your body and soul or to actually check the chart. While hove to has the advantage that other boats can easily manoeuvre around you, wouldn't it be nice to stay on course while you leave the tiller? The safety and convenience of it all is sheer decadence, especially if you are passage making when distance and time are so important. Think of all the things you can do while "Otto" is steering. You could actually arrive relaxed, with all your boat jobs done! Now there's a novel thought. VARIOUS AUTOPILOTS -

NOTE: One of the limitations with the original model

Autohelm or the later version Tiller Pilot is that they react too slow in

a rough sea state, especially downwind. The slow adjust rate is

perfectly fine when motoring but too slow when sailing in deep waves

or gusty winds when larger steering angles are required to maintain a

straight course. It is extremely hard on the gears, the motor and the current draw when the control rod is pushed to the end of its travel. I have seen a unit

that stripped its gears trying to maintain a course in these

conditions.

"I have it on good advice from the

factory that a

Tiller Pilot cannot

maintain a course sailing in heavy wind. It is beyond the limits

of the hardware to do this." For this reason several sailors I know only use their unit when

motoring, changing sails or to relieve the helm for a short time while

they are preoccupied with an urgent bio task. Other than this, they

secure the helm with a Tiller Tamer or steer manually. As a result

their low end unit doesn't wear out and it is available when they

really need it, motoring into a harbour or for a long passage.

My cockpit mounting hardware consists of the removable wood block shown here. It may be less elegant than the factory option but it is strong enough to stand on and leaves the cockpit wall flat when removed. The water proof screw mounting hole fits flush to the backrest to prevent injury. The 3" SS screw through the wood block is held captive so I can't loose it. After many years of leaving the screw mounting hole open I now keep a screw in it to keep it clean. All of this due to a spider that decided to make lay eggs in there. Unfortunately for the spider, I decided that I can make better use of this hole! Good riddance. I rejected the factory cockpit mounting hardware for two reasons:

The cockpit electrical connector for the Tiller pilot was installed in the foot well below the Tiller Pilot where it is easy to extend the boat wiring harness to. It is fairly easy to line up the key pin to plug the cable in and the backrest is unobstructed, as is the port hatch when the Tiller Pilot is in place. Replacement Bulkhead Connector - Order here. The factory direction controls on Panache's Tiller Pilot are labeled for a starboard installation and therefore backwards for a port installation. For straightforward logic to steer by I affixed direction labels (arrows) on the case to indicate port or starboard without having to think through the + & - logic.

I fabricated a stainless steel mounting bracket for the tiller pin (shown above) so it can't snag anything. It is also much stronger than the factory single ended arm and can't bend under load.

ELECTRICAL WIRING - The Raymarine ST1000+

or

ST2000+ Tiller Pilots

are capable of being controlled

by an external NMEA 0183 compatible device (GPS navigation receiver, plotter, etc) to follow a programmed route over the

ground. This is superior than using the "hold this heading" switch

when operating the boat through a cross current or cross wind. To this end I installed a

voice grade (Cat 3) wiring harness from the cockpit connector to the

GPS. The harness

runs inside a cable tray along the top inside of the port locker, through the port cabin bulkhead (sealed with sealant), and across

the cabin behind the companionway to a terminal

strip below the VHF. This

where it is cross connected to the

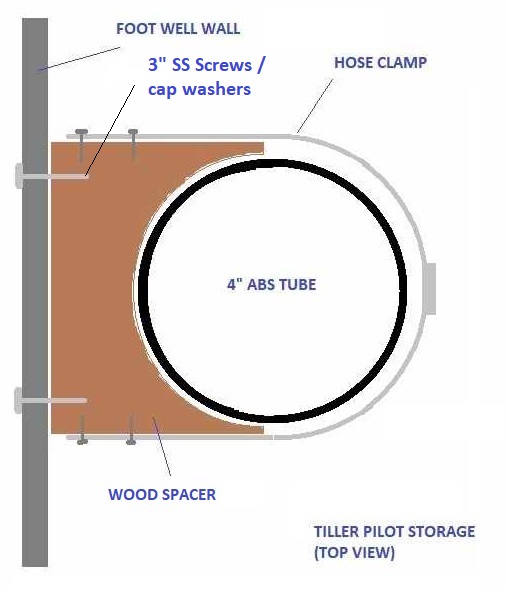

STORAGE - For many years I stored my Tiller Pilot behind a settee back rest, wrapped in a towel & protected from the weather. I was reluctant to store it elsewhere, the spot is that dry and secure. But, retrieving it took too long when sailing solo and Panache was sometimes well on her way to a new heading by the time I popped my head out of the cabin. "I hate it when the jib is back winded." So the Tiller Pilot was moved to new storage in the cockpit locker which is in keeping with my philosophy of, "Store it where you use it." It's now stored inside a (22x4)" ABS tube mounted inside the port locker, against the foot well wall. This is easier said than done, given the tight confines of the locker. The ABS tube is mounted at a slope (aft end lower) to drain water out. The open end just protrudes into the aft end of the locker opening where it can't interfere with removing the false floor below it (See Tech Tip D02). The two wood spacers that support the tube are not shaped quite as shown above but you get the idea. They required a bit of finagling to make them fit over the cable tray I previously installed (Tech Tip D02) along the top of the locker. The spacers are coated with epoxy to seal the wood. The oversize SS hose clamps were split in the middle, cut to length and screwed to the spacers for maximum holding power. The tube is long enough that the unit will slide in fully. The bottom end of the tube is stuffed with high density foam padding with a hole in the middle to receive the Tiller Pilot actuating rod. It is not required to have a cap or to line the tube with a soft fabric for chafe protection.

It took a considerable amount of planning and contortion on my part to install this storage tube on my own since I had to install it over the cable tray. After crawling into the locker with the assembled unit, I positioned it against the wall and drew an outline of each foot print, with screw hole marks inside each. Using a tiny bit I drilled four holes from the inside through to the cockpit. The next part got even trickier. While straddling the locker wall to hold the unit in place, I drilled (from cockpit side) back into the feet to create pilot holes for the 3" mounting screws. The front top screw went in first which gave me a reference pivot point for drilling the back screw holes. You have to get creative when you work on your own. It helps to have a right angle electric screw driver. The Tiller Pilot slips real easy into the holder. I even found a spot down there to store the wood pedestal socket that the Tiller Pilot operates from. Everything is extremely convenient to access. I like modification this a lot. NOTE - Use this locker for electronic storage only if it is bone dry. If it is wet, corrosion will likely ruin the unit.

|

|

|

Return to Tech Tip Index. . . . . . . . . . . . . . . Have a Question? |

|

GPS to

operate using NMEA sentences. See

GPS to

operate using NMEA sentences. See