| SJ23 Tech Tip F10, (Updated 2024-11-11)

Stan Franklin, Ralph Fuchs, Alan Weld, Randy Cook, Robert Hasegawa & Bob Schimmel. |

Index |

|

Roller Furling for Panache.

Index -

Harken 00AL, CDI FF2,

Hood Seaflex, Selden/Furlex,

Alado.

PANACHE INSTALLATION -

Schaefer CF-500,

A new Forestay,

Assemble Furler,

Furling Control Line.

Replace a Damaged Forestay,

Reference Links.

|

The reliability of a jib furling system on a pocket cruiser is beneficial for a

solo sailor since reducing sail area quickly from the safety of the

cockpit is your safety valve. It eliminates a trip to a pitching foredeck that can

require a fair degree of balance in steep waves. Then there is the

issue of leaving the tiller while the boat does squirrelly things all on its own. The reliability of a jib furling system on a pocket cruiser is beneficial for a

solo sailor since reducing sail area quickly from the safety of the

cockpit is your safety valve. It eliminates a trip to a pitching foredeck that can

require a fair degree of balance in steep waves. Then there is the

issue of leaving the tiller while the boat does squirrelly things all on its own.

For a trailerable sailboat the easy collapsibility

(for lack of a better word) of the

standing rigging is important when the mast comes down at the end of a season. I have seen many an expensive aluminum foil get kinked

or bent while stepping the mast with little to no damage while sailing. Damage can also occur during road travel, which is usually due to inadequate

support for the foil & drum.

The simple task of lashing a support pole to the mast or removing the

drum escapes some people! The damage is sometimes impossible to

repair and requires expensive replacement.

While I'm not trying to talk you out of installing a

furling system, but failures due to component weakness or

corroded bearings are two of the reasons why die hard sailors of the

1970s, including yours truly, stayed with a hank on jib and a down haul line. Thankfully flexible furlers are dependable today

due to improved foils

and drums to prevent salt water corrosion and Torlon ball bearings to make it easy to turn. The advantages of a correctly

installed flexible system are; ease and speed of use, less fatigue,

dependability, fewer bagged sails cluttering the cabin and a drier cabin since you are not hauling wet

sails inside. I am not going back to hanked sails.

Read Tech Tip F10a, "How to keep your furling

system alive" before you install your new system. You can glean some really good rigging tips from Brion Toss. VARIOUS FURLERS TO CONSIDER FOR AN SJ23 -

The difficulties of designing a strong furling system that can be shipped

easily have been solved. Two techniques have evolved; sectional aluminum extrusions

that are screwed together for installation or a flexible vinyl extrusion that is rolled in a coil for shipping and cut to length for installation.

Hence the term flexible furler. The furlers shown in this Tech Tip are operational on various SJ23s. See

Tech Tip H02

for

rigging specifications to assist you in choosing a furler.

TOP

HARKEN 00AL

-

This

sectional furler (shown at right) has the following features;

| BOAT |

Designed for an (18-26)' or (6-8)M

sailboat.

|

| FORESTAY |

To install this

furler you must cut the forestay and purchase a Harken clevis pin

to match your chain plate.

|

| TURNBUCKLE |

Requires an open turnbuckle with

T-bolt & toggle at the bottom. An open turnbuckle can easily

be lock wired.

|

| FOIL |

The early

version of this furler has a double grooved sectional aluminum

oval foil up to 31' long that can be built out to 35'. Later versions of

this furler have vinyl foil.

|

| DRUM & TORQUE TUBE |

The torque tube has a free spinning omni directional ball bearing

system with multiple bearing races. A large spool for easy reefing or furling.

The split drum can be removed for racing or road transport.

|

| FURLING CONTROL LINE |

Single line, about 40' of 5/32"

or 3/16" braided Dacron. Install 1 swivel block on pulpit &

2 fairleads on stanchions.

|

| SAIL |

#6 luff tape with webbing on the tack and head recommended to avoid

bulky furling.

A UV strip along the foot and leech is recommended to protect the

cloth.

|

| HALYARD |

Lightweight halyard swivel.

The halyard should be lead 10 degrees away from the forestay to

prevent halyard wrap.

|

| INSTALLATION TEMP |

20C or warmer.

|

The entire system can be removed from the forestay

but it would be a lot of work. (Harken furling 101)

"The roller furling on

Sail Boar is a

Harken 00AL. It has a flexible two track foil and the furling

drum is a split design that can be removed for trailering or racing.

This frees up the full length of the forestay to attach the largest jib

possible. I purchased the Harken 00 from the North Sails, Vancouver

loft for approximately $1000 CA, (1996). Dave Miller at North Sails

also removed the extra roundness of my 135 genoa and installed UV

protection along the leech and foot for about $250. The loft needs

the forestay length of the furling system to modify the sail. The

installation of the furling gear is fairly routine since the system uses

the existing forestay and turnbuckle. While Harken says, "It should not be necessary to install a

halyard restrainer at the masthead," they are wrong. This is essential, unless you enjoy running up the mast to clear a wrap! halyard restrainer at the masthead," they are wrong. This is essential, unless you enjoy running up the mast to clear a wrap!

The

Harken 00AL works very well for single-handed sailing. The

furling control line is fed back along a lifeline to the cockpit. My converted 135% genoa still has reasonable shape

when partially furled. On Dave Miller's advice, I also converted a

"Blade" as a heavy weather sail but so far have not hoisted it. From my experience the Harken system

is built first class and virtually bullet proof."

Stan Franklin.

PREVENT

a HALYARD WRAP - A wrap can be a real nuisance when you can't undo it,

leading to forestay failure in a worst case scenario.

Take every precaution you can to prevent one. "The extra block installed on the mast

for the halyard is a modification I made after the

Harken 00AL roller furling was

installed. The jib halyard (green tracer) and the forestay through

the furling foil were almost parallel to each other. The forestay

(pulled away from mast for visibility) is attached just above the green

halyard. Because they were almost parallel, there was a risk of

wrapping the halyard around the forestay when operating the furling

system. It never actually happened but came pretty close a few

times. The solution was to add the block on the mast and run the

halyard through it, thereby increasing the angle between the head stay

and the halyard."

Ralph

Fuchs.

TOP

|

|

CDI

FF2 - In 2012 I helped install a CDI FF2 flexible furling

system on a friend's MacGregor and was impressed with the robust

simplicity of the hardware. Especially the one piece tough vinyl foil that has

incredibly high torque properties. This was my

first time to install a flexible furler. Once assembled

it was easy to push the drum and foil up to adjust the turnbuckle.

Overall this is a very clever design that fully incorporates the kiss

principle. I've since seen this system installed on other sailboats,

all operating with no problem. The hardware can be removed from the forestay.

It comes with a life time warranty to the original owner. Bob Schimmel. CDI

FF2 - In 2012 I helped install a CDI FF2 flexible furling

system on a friend's MacGregor and was impressed with the robust

simplicity of the hardware. Especially the one piece tough vinyl foil that has

incredibly high torque properties. This was my

first time to install a flexible furler. Once assembled

it was easy to push the drum and foil up to adjust the turnbuckle.

Overall this is a very clever design that fully incorporates the kiss

principle. I've since seen this system installed on other sailboats,

all operating with no problem. The hardware can be removed from the forestay.

It comes with a life time warranty to the original owner. Bob Schimmel.

-

"One of the sailors at a local club on

Wabamun Lake contacted North Sails in the Spring of 1997 about

installing a Harken 00 system on his MacGregor 26. This time Dave

Miller recommended the roller furling system made by

Cruising Design Inc. (CDI). Boat

Journal apparently rated it #1 among flexible furlers for trailerable

sailboats. The unit was installed on the MacGregor 26 without any problem over the

existing forestay. The foil has a single track but the drum cannot

be removed for racing, if that is important. The components have a lifetime warranty to

the original owner.

The cost in 1997 from North Sails in Vancouver was about $850.00

Ca. The Cruising Design system is somewhat less expensive than the

Harken unit and according to Dave, more reliable." Stan Franklin.

- "I love my FF2 and have had no

problems with it. However, it is not rated for my 150% jib and if

I had to do it over again, I would buy the FF4, the next size up. In addition, the FF4 drum is larger so it can handle larger line which is easier on the hands. I did buy

the FF2 model equipped with the synthetic ball bearings so it rotates easier under load. As a result my FF2 is very smooth and

operates well

when the wind pipes up." Alan Weld.

The Cruising Design Inc. web site shows a good explanation of the

hardware for all four models. Their specs will guide you to the

model FF2 that fits the SJ23 with a 29' 3" forestay. For assistance 1(844) 379-2407 or

info@sailcdi.com.

|

BOAT |

Designed for an (18-26)' or (6-8)M

sailboat.

|

|

FORESTAY |

1x19 SS, 1/8" to 3/16" wire.

|

|

TURNBUCKLE |

Requires an open turnbuckle with

T bolt & toggle at the bottom. An open turnbuckle can easily

be lock wired.

|

|

FOIL |

A flexible one piece oval extrusion

with stainless steel cable co-extruded into the vinyl foil to minimize

twist. Single track. Max length, 28'.

|

|

DRUM & TORQUE TUBE |

Can slide up to adjust

turnbuckle. Bushing is standard. Synthetic bearing is

optional and can be added later.

|

|

FURLING CONTROL LINE |

Single line, about 40' of 5/32"

or 3/16" braided Dacron. Install 1 swivel block on pulpit &

2 fairleads on stanchions.

|

|

SAIL |

#6 Luff tape with webbing at the

tack and head to avoid bulky furling.

A UV strip along the foot and leech is recommended to protect the

sail cloth.

|

|

HALYARD |

Can't happen with the CDI furler which means you can

hoist a jib with any length luff.

|

|

INSTALLATION TEMP |

20C or warmer.

|

The drum can be slid up the foil to expose

the turnbuckle for adjusting. Once adjusted, the head stay tension

is set by the backstay adjuster. See

Tech Tip F09.

INSTALLATION - I installed a CDI FF2 on Wild Tangent during a weekend using Sta-lok fittings with the mast standing. This created a couple challenges that were easily resolved after I figured out what to do. Installing a CDI FF2 with the mast standing and the boat in the water requires a spinnaker and jib halyard as a temporary forestay to keep the mast standing. Below is a high level summary that might help others. Robert Hasegawa (2024-11-11).

Make sure your forestay is properly tensioned and mark the proper location on the screws with tape. There is no way to put a Loos gauge on the head stay after the foil is installed.

- Measure the mast rake and the backstay tension with a Loose Gauge prior to this installation. If the mast rake and the backstay tension are the same after the installation, assuming the new forestay is the same length, then all is OK. Assemble the FF2 head fitting as per CDI instructions. For Sta-lok fittings. Enlarge the center hole on the bow end of the foil to .5" diameter x 3” deep. The CDI foil is designed to slip over a swaged fitting, but Sta-lok fittings are much larger in diameter. Peck at the extrusion with your drill in a controlled way or it will “cork screw” into the material. This step is not required for a swaged fitting. Attach spinnaker halyard to the stem head fitting to function as a temporary forestay. Loop the jib halyard around the top of the foil and attach the jib shackle to the halyard making a “noose” of sorts. This will be used to hoist the foil. Do not wrap this around the halyard, only the foil. That is part of the CDI system. TIE A MESSENGER LINE TO THE JIB SHACKLE. This will be used to retrieve the shackle once installation is complete. Remove the forestay pin and remove the Sta-Lok fitting from the cable. Feed the cable through the center hole of the foil. Use the jib halyard to hoist the top side of the foil while carefully feeding the cable into the center hole. At some point, the end of the foil will be beyond reach. Just pull the halyard carefully, wiggle it around if necessary, and it will feed all the way through. I did this on the first try with no problem. When the end of the cable is through, cleat the jib halyard. You should have a few inches of cable sticking out the top. Reinstall the Sta-Lok fittings using a new wedge and former. Continue the drum installation per the CDI instructions. Re tension the head stay using the tape. Safety wire in place. Uncleat the jib halyard and use the messenger line to retrieve the shackle. Job done. Check the mast rake and backstay tension after a couple of weeks. Don't be surprised if it requires adjusting to restore settings.

TOP

|

|

HOOD SEAFLEX FURLER -

Incorporating all the experience and quality of HOOD Yacht Systems, the

SEA FLEX flexible furler is created with

the needs of a pocket cruiser in mind.

|

BOAT |

Designed for an (18-26)' or (6-8)M

sailboat.

|

|

FORESTAY |

Forestay 1x19 SS, 1/8" to 3/16" wire.

|

|

TURNBUCKLE |

Requires an open turnbuckle with

T bolt & toggle at the bottom. An open turnbuckle can easily

be lock wired.

|

|

FOIL |

A flexible one piece oval extrusion

with stainless steel cable co-extruded into the vinyl foil to minimize

twist. Single track. Max length, 33'.

|

|

DRUM & TORQUE TUBE |

Removable drum covers and guard

for performance sailing. Universal clevis mounting. Tapered

drive unit for clean sail entry.

|

|

FURLING CONTROL LINE |

Single line, about 40' of 1/4"

braided Dacron. Install 1 swivel block on pulpit,

2 fairleads on stanchions, 1 swivel block at the aft stanchion, a

cleat on the cockpit coaming away from sheet activity.

|

|

SAIL |

#5 Luff tape with webbing at the

tack and head to avoid bulky furling.

A UV strip along the foot and leech is recommended to protect the

sail cloth.

|

|

HALYARD |

The halyard should be 10

degrees away from the forestay to prevent a wrap.

|

|

INSTALLATION TEMP |

15C or warmer.

|

The drum can be released from the furler housing and the side of the

housing removed to expose

the turnbuckle for adjusting. Once the turnbuckle is adjusted to the correct

mast rake the head stay tension

is set by the back stay. See

Tech Tip F09. The drum can be released from the furler housing and the side of the

housing removed to expose

the turnbuckle for adjusting. Once the turnbuckle is adjusted to the correct

mast rake the head stay tension

is set by the back stay. See

Tech Tip F09.

"I acquired this system with the

purchase of my boat. After I replaced the missing components all

is working well with the boat on the trailer. The 150% genoa rolls

up nicely. Once the boat refurbish is

complete I'll report my on the water experience here." Randy

Cook.

TOP

|

|

SELDEN / FURLEX 50S FURLER - Perfect choice for a sailor

wanting a compact, low height furling and reefing system. This is

the

only manufacturer to supply a complete kit of the following: a new forestay wire

e/w Sta-Lok terminal, halyard lead, stanchion block,

pre-feeder and furling control line with the furler. Everything included. Here's

how to install it and

measure it.

| BOAT |

Designed for an (18-26)' or (6-8)M

sailboat.

|

| FORESTAY |

1x19 SS, 4-5 MM equipped with Sta-Lok

terminals.

|

| TURNBUCKLE |

Fork and toggle mounting.

|

| FOIL |

Flexible one piece vinyl

oval extrusion. Max length is (7.7-10.1), (7.7-12.5) M.

|

| DRUM & TORQUE TUBE |

SS sail feeder for smooth

hoisting.

|

| FURLING CONTROL LINE |

Single line, about 40' of 1/4"

braided Dacron. |

| SAIL |

#6 Luff tape with webbing at the

tack and head to avoid bulky furling.

A UV strip along the foot and leech is recommended to protect the

sail cloth.

|

| HALYARD WRAP |

The halyard should be 10

degrees away from the forestay to prevent halyard wrap.

|

| INSTALLATION TEMP |

15C or warmer.

|

TOP

|

|

ALADO

- Another good sectional furler for an SJ23. It has lifetime

warranty, double sheaves for twin sails, double integral halyard

sheaves, dual interlocking aluminum foils for aerodynamic profile and

optimum torsion strength, polypropylene bushings, no swivel under

tension to jam eliminating halyard wrap, open drum. Furling drum,

sheave boxes & luff feeder are made from aluminum. The aluminum

foils rotate on bearings around the forestay, keeping it centered and

straight.

TOP

|

|

PANACHE

INSTALLATION (2018-04) - "I had

no intention of installing a furling system but I'll admit that I was getting

tired of the "panic" trips to the foredeck to douse a jib. Then in Fall of 2017

I was offered a

Schaefer Snapfurl CF-500 furler for a

price I just couldn't turn down. tired of the "panic" trips to the foredeck to douse a jib. Then in Fall of 2017

I was offered a

Schaefer Snapfurl CF-500 furler for a

price I just couldn't turn down.

FORESTAY

- A new furler also meant I had to install a

new forestay and of course a 'perfect time' to install a

back stay adjuster. See Tech Tip F09. FURLING CONTROL LINE

-

The design of the furling control line was reconfigured several

times to accommodate my anchor roller which lead to installing the fairlead bracket (CF-500-22) on the drum, fairleads on the stanchions and roller blocks along the toe rail. CONVERT JIB

- During installation I thought it expedient to

convert my 110% jib to furling since I knew

it would fit, so off it went to North Sails, Vancouver. JIB SLEEVE

- Since I already owned

a slightly used

jib sleeve I chose not to add UV strips to

the jib. JIB OOPSY

- A problem with the top pennant of the 110% jib was solved with trial and error during the

first summer. CONVERT GENOA

- The next summer my 150% genoa was converted to furling.

SCHAEFER

SNAPFURL CF-500 - An excellent USA built flexible furler with a

flexible foil designed specifically for stepping the mast of a

trailerable sailboat. This is perfect if you frequently step the

mast as it is less prone to damage while doing this

job. It is easy to store on the mast for transport. It comes with a 5 year warranty to the original

owner. (Keep your receipt). The vinyl foil extrusion halves are coiled and shipped in a (36x36x5)" box

with the associated hardware tucked inside. Keep that in mind for shipping.

The two foil halves, fore and aft, snap together over a 1/8" to 3/16"

diameter forestay. The swivel and drum are equipped with Torlon

bearings. The swivel slides to the top of the foil to hoist the

jib and tension the

luff. The drum is equipped with a retaining clip and a locking

strap to keep the turnbuckle toggle extended out the bottom for

"pinning" the forestay to the deck. This is a clever design that

allows a person to push the torque tube down to guide the turnbuckle into

place over the chain plate, saving time by keeping

parts attached. Once the forestay is on, the drum can be

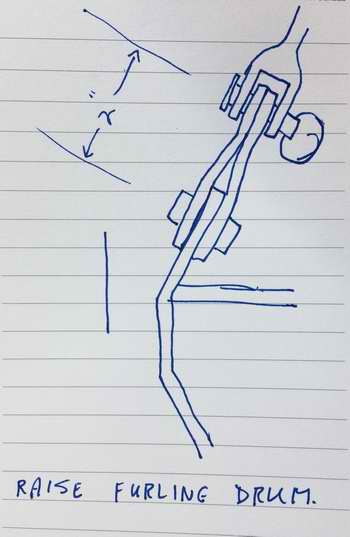

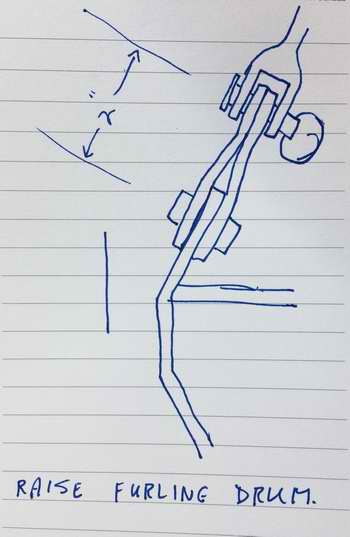

slid up the foil by loosening 4 captive 5/32" Allen screws on the

sail feeder and the two screws on the bottom locking strap you see at right. Sliding the drum up over the foil exposes the turnbuckle so the tension can be adjusted.

Once the turnbuckle is adjusted with the correct mast rake it is lock

wired and the head stay tension is set by the back stay. This is why I

installed a back stay adjuster on Panache. See

Tech Tip F09. To remove the drum and swivel for winter storage loosen the 4 Allen screws and slide both off the bottom of the foil. For road travel and storage secure the

foil with enough straps along the mast to prevent drooping and support the protruding end of the foil. The alternative is to support the

torque tube with a (2x4)" or ski pole. SCHAEFER

SNAPFURL CF-500 - An excellent USA built flexible furler with a

flexible foil designed specifically for stepping the mast of a

trailerable sailboat. This is perfect if you frequently step the

mast as it is less prone to damage while doing this

job. It is easy to store on the mast for transport. It comes with a 5 year warranty to the original

owner. (Keep your receipt). The vinyl foil extrusion halves are coiled and shipped in a (36x36x5)" box

with the associated hardware tucked inside. Keep that in mind for shipping.

The two foil halves, fore and aft, snap together over a 1/8" to 3/16"

diameter forestay. The swivel and drum are equipped with Torlon

bearings. The swivel slides to the top of the foil to hoist the

jib and tension the

luff. The drum is equipped with a retaining clip and a locking

strap to keep the turnbuckle toggle extended out the bottom for

"pinning" the forestay to the deck. This is a clever design that

allows a person to push the torque tube down to guide the turnbuckle into

place over the chain plate, saving time by keeping

parts attached. Once the forestay is on, the drum can be

slid up the foil by loosening 4 captive 5/32" Allen screws on the

sail feeder and the two screws on the bottom locking strap you see at right. Sliding the drum up over the foil exposes the turnbuckle so the tension can be adjusted.

Once the turnbuckle is adjusted with the correct mast rake it is lock

wired and the head stay tension is set by the back stay. This is why I

installed a back stay adjuster on Panache. See

Tech Tip F09. To remove the drum and swivel for winter storage loosen the 4 Allen screws and slide both off the bottom of the foil. For road travel and storage secure the

foil with enough straps along the mast to prevent drooping and support the protruding end of the foil. The alternative is to support the

torque tube with a (2x4)" or ski pole.

| BOAT |

Designed for an (18-26)' or (6-8)M sailboat.

|

| FORESTAY |

1x19 SS, 1/8" to 3/16" wire. I

replaced Panache's forestay.

|

| TURNBUCKLE |

Requires an open turnbuckle with

T-bolt & toggle at the bottom so it can be wire locked.

|

| FOIL |

A flexible one piece round extrusion made from high grade Geon PVC. Single track. Max length, 31'. The instructions provide clear step by step directions for cutting the foil to the correct length.

|

| DRUM/TORQUE

TUBE |

An injection molded drum/torque

tube equipped with Torlon bearing(tm) and SS sail feeder. Once the sail feeder is loosened and the retaining clip removed, it can slide up

the foil to adjust

the turnbuckle. While the torque tube does not touch the open turnbuckle inside it,

Schaefer recommends lock wiring the turnbuckle to prevent accidental

unscrewing.

NOTE - Like most furling systems this one also benefits from an external prefeeder to load the jib onto the foil, unless you enjoy walking to the drum to guide each foot of sail into the prefeeder.

|

| FURLING CONTROL LINE |

Single line, ~40' of 1/4"

braided Dacron. Install a swivel block on the toe rail just

aft of the pulpit and a SS fairlead on each stanchion. Install the cleat away from the primary winch. If

the cleat is installed at the aft end of the

cockpit coaming you will also require a swivel block mounted on the aft

stanchion to turn the line forward.

|

| SAIL |

#5 Luff tape (standard & good

quality, CANNOT BE HEAVY) with webbing at the tack and head to

avoid bulky furling. To protect the cloth from UV damage

install a UV strip along the foot and leech or use a jib sleeve.

|

| HALYARD |

Requires a halyard restrainer

attached to the top of the mast so the halyard is angled at least 100 away from the forestay

with the swivel within 5" of the foil cap.

If the sail is not full hoist a pennant is required between the head

and the swivel so the swivel

is within 5" of the foil cap. It is OK to add a

short pennant at the tack.

NOTE - A correctly positioned foil restrainer can prevent the swivel

from being pulled off the top of the foil.

|

| INSTALLATION TEMP |

150C or warmer.

|

PANACHE

Measurements

for Schaefer CF-500 |

(Forestay =

29' 3-1/4"), (Foil LOA = 28' 8.5"), (Foil clevis/clevis = 27' 6"), (Jib luff = 27' 3").

NOTE - These measurements apply to Panache. Use them as a guide. You MUST measure the dimensions for your own boat.

|

-

Locking strap and turnbuckle retaining clip - Schaefer equips

this furler with a locking strap (holds torque tube up) and a

turnbuckle retaining clip (holds torque tube down) installed below the

drum (read the CF-500 manual). With both installed the drum/torque tube can't slide on the forestay, making it possible to pin the forestay to the deck by pushing down on the drum. In

Panache's case the turnbuckle toggle didn't stick out far

enough to easily pin the forestay, so I added a

3/4" spacer and a custom retaining clip.

- Schaefer Lead Arm - The CF-500 drum installs too low to the deck of an SJ23 to

install the first

control line block on a pulpit leg, there being no 900 line

up. This is the reason

I installed the Schaefer Lead Arm, option CF-500-22. It works

well.

-

Sail

Feeder - The

square corners on the inside of the metal sail feeder make removing a jib very

difficult when the bottom of the luff tape has frayed

cloth that binds on the inside square corners of the sail feeder. (Later

I learned they should be bonded to each other). One of the loose outside layers of cloth will inevitably pile up on

one side of the top of the feeder, preventing the sail from sliding out. This was

the case with my modified jib. In an emergency it is

possible to remove the feeder and pull the foil up to remove the jib.

A better solution is

to glue the 1/2" edge of layered cloth into a single rigid form.

The glue must not be longer than 1/2", as it must slide through the .062" gap of the feeder. DO NOT GLUE THE

BEAD as it must remain flexible to slide through the feeder. In addition, I filed the inside

corners of the feeder to a slight bevel and polished the bevels with

600 grit emery cloth. Voila, the jib slips in and out much

easier.

-

Prefeeder - Its also a good idea to use a pre-feeder to guide the jib to the

foil feeder, especially if you hoist the jib on your own. It's really frustrating having to walk

between the bow and the mast for each foot the jib is

hoisted, not to mention damage that can be done to the luff tape by snagging

it on the

foil feeder. The best prefeeder is one equipped with rollers at

the business end.

Transport & Storage - For trailering and winter storage

Schaefer recommends the drum and swivel

be slid

off the foil and stored in the cabin to remove excess weight. Transport & Storage - For trailering and winter storage

Schaefer recommends the drum and swivel

be slid

off the foil and stored in the cabin to remove excess weight.

- On

Panache the foil protruding beyond the mast is supported by an old ski pole jammed into the top hole in the mast base. This works very well and simplifies the job.

- One less hole for the birds to nest in!

- Alternatively you can support it with a (2X4)" as shown for a CF-700 furler ready

for a trek down the lake. In either case there is no strain on the drum or

foil.

|

|

A NEW FORESTAY

YOU SAY

- When you read the installation manual of any of these

flexible furlers you'll discover all of them recommend

replacing the forestay if it is even slightly suspect OR more than 4 years

old. Selden goes so far as to supply a new forestay! All

of them recommend using an open turnbuckle that is locked with SS wire since a roller furler has been known to unscrew a

locked barrel type turnbuckle. "Nasty that would be."

An open turnbuckle sheds water & debris where a barrel turnbuckle can trap

both. I have no access to a rigging shop to

swage a new 1/8" forestay so I upgraded it to 316 SS 5/32" wire (left hand lay) with a Sta-Lok eye terminal at the top and a Sta-Lok 5/16"

turnbuckle stud terminal at the bottom. 5/32" wire is more robust

than 1/8", has less stretch and a Sta-Lok terminal can be repaired in the field.

-

Keep this in mind. "Corrosion resistance, fatigue resistance, proper scantlings, proper tune, proper use, and quality of metallurgy are all more likely to prevent rigging failure than ultimate strength will. Rigging afloat is very unlikely to be stressed anywhere near the breaking strength of its mechanical fittings but Mother Nature is always acting to corrode, fatigue or otherwise break it." Practical Sailor.

-

Just in case you have the heebie

jeebies about installing a mechanical

terminal, watch the applicable "how to" video: Sta-Lok,

Hi-Mod (Hayn) or Norseman. (Norseman

went out of business in 2014).

-

A marine sealant

can displace the water and air inside a compression

terminal to prevent cracking in freezing weather and/or crevice corrosion in salty air. Sta-Lok leaves the decision to fill the terminal to the installer as long as the

sealant is not acidic. Suitable sealants are:

Sikkens Sikaflex 291, marine silicone sealant (with no vinegar smell), 3M4000 UV or BoatLIFE polysulfide.

- I live in a

freezing climate so filled Panache's terminals with

Sikkens Sikaflex 291.

STEPS to INSTALL a

Sta-Lok

TERMINAL.

|

|

To replace the factory forestay and turnbuckle I installed the bottom Stay-Lok terminal first and placed the turnbuckle eye on the measuring board, next to the old forestay (Board shown for demo only). Then I tightened the forestay and the 5/32" wire side by side to transfer the LOA to the new wire. Stretching was done with the turnbuckle screwed in 1/3 of the way which so you can adjust the mast rake as needed for sailing. I measured the LOA a zillion times before I finally cut it as I had very little extra wire.

|

|

Fig 1, CUT WIRE SQUARE - Tape the wire to keep the strands together

while cutting through the tape. It cuts absolutely square

without burrs if just the weight of the hack saw cuts the

strands with support from a (2x4)". The alternative is to use a Dremel tool with a cutting disk using light pressure.

|

Fig 2, ASSEMBLE THE TERMINAL - The socket was slid over the wire & the outside strands unravelled. The wedge was slipped over the core leaving 1/8" protruding. The outer strands were evenly spaced around the

wedge & across the split. The socket was slid against the strands to

maintain their spacing. Then I held the end fitting with the open end pointed up so the former stayed on the bottom. 1 drop of Loctite went on the former and 2 drops on the socket thread. The two were tightened till just snug.

|

|

Fig 3, FORM THE STRANDS - I removed the end fitting to confirm correct forming and even spacing of

the strands as per this photo. The center

core MUST stick out a bit. It fits in the hole through the former, provided the burrs were removed. Wet Loctite is an excellent lubricant to use between the strands and the face of the former. Also on the

thread to prevent galling. Once cured it prevents the

Stay-Lok terminal from working itself loose. The terminal can be opened

for inspection years later, provided you replace the wedge. I haven't done this yet.

|

Fig 4, SEAL THE TERMINAL - The excess Sikaflex oozed out between the wire strands and the thread when I tightened the end fitting. The sealant guarantees a water tight seal to prevent corrosion in this deck level terminal. The threaded stud end was tightened on the stationary socket to maintain the integrity of the wire strands against the former.

While I used a wee tad too much Sikaflex, it turned out good. Its not often that the stud end is shown. This screws into the top of a turnbuckle. It sure simplifies the rigging assembly.

|

|

Fig 5, TOP

TERMINAL

- I determined the cut length of the new forestay by lining up the Stay-Lok pin hole to the factory masthead toggle hole. The black pointer indicates where the wire ends inside the Stay-Lok terminal. The forestay length is crucial to maintain mast rake.

|

Fig 6, TOP

TERMINAL - Top Stay-Lok terminal installed on the

new forestay.

The excess Sikaflex was wiped off leaving some embedded between the strands to shed water. The black pointer indicates the alignment of the clevis pin hole to the factory forestay toggle hole.

|

|

The San Juan mast head toggle was retained to pin the Sta-Lok eye to. The toggle spreads the load evenly on the horizontal pin across the masthead.

Back to Tech Tip F34a

|

With the new forestay fabricated the "cut length" of the Scheafer vinyl foil was measured for installation. Then the maximum luff length of the 110% jib was measured for conversion (first sail to be converted). These two critical measurements were made with a 100'

tape measure to ensure accuracy. Now we're making progress.

|

|

TIME TO TEST - There comes a time in any project when you just have to put

the pieces together to confirm that things fit before moving to the

next critical step! So on a warm Spring day Panache's mast was stepped using the factory backstay

to maintain the original mast rake. The new forestay was a perfect fit with the mast at the

correct rake and 1" of thread left on the turnbuckle. Its sweet when all the measurements are correct

and things fit. Next step is to

install the furling system.

|

|

INSPECTION (2023) - Inspecting the forestay turnbuckle should be done on the hard prior to launch where it's somewhat easier to find a dropped part. Just say'n. If you inspect it on the water it means more work, since sliding the drum/torque tube up to expose the turnbuckle demands that you remove the jib and not drop anything.

"By the way, inspecting the turnbuckle during the winter with snow on the ground is about as intelligent as inspecting it on the water! Naturally I inspected Panache's turnbuckle on the water because I forgot. But at least I did this on a calm day before the jib was hoisted with both halyards attached to the pulpit to support the mast. Thankfully the temporary lock wires were still in place and the grease on the thread was still good after 5 years of service. No problems after all. Phew. However, in Spring 2024 I replaced the temporary wires with permanent SS wires. Nothing wrong with the temporary wires but I like SS better."

TIP: One way to monitor the length of the forestay, terminals and turnbuckle is to measure the mast rake. The rake is the sum of all adjustments. It's peace of mind to see no change. But you should still visually inspect the terminals and turnbuckle on a regular basis. Panache's rake is ~6" aft at the foot.

|

|

|

TOP

|

|

ASSEMBLE

FURLER - "Prior to installing a CF-500 furler on Panache in Spring

2018, the system was

assembled and tested on a new 5/32" forestay stretched between two trees.

Its a lot easier working horizontal on the ground than vertical on the boat!

Besides, the lake was still frozen.

It took two of us to snap the foil halves together, one to guide the

curled extrusions and the other to snap them together. As curled as the extrusions were

coming out of the shipping box, its

amazing they snapped together to form a fairly straight foil that

rotated easily on the forestay. To "help

it" acquire a new memory of being straight

I left the assembled foil to bake in the sun for several days, stretched between those two trees.  The 2' end section that didn't want to straighten was "persuaded" to do so with a

heat gun. The top of the foil

terminates about 2" from the end of the new forestay. The

halyard restrainer was installed on the front of the mast, level with

the top of the foil. The 2' end section that didn't want to straighten was "persuaded" to do so with a

heat gun. The top of the foil

terminates about 2" from the end of the new forestay. The

halyard restrainer was installed on the front of the mast, level with

the top of the foil.

NOTE - The halyard

restrainer MUST be attached very securely to the mast if you use the

halyard to step the mast. Its worthwhile to check these fasteners every once in a while!

PIN THE FORESTAY UNDER THE LOW FURLING DRUM - After a few

frustrating times

to pin Panache's forestay while stepping the mast I needed a

better solution for the drum installed low to the deck. The

Schaefer manual shows a sideways pin installation that would work well

for a low drum installation but offers

no suggestion for a fore aft pin configuration as on an SJ23.

While some sailors like a low drum for a deck sweeper jib, this sailor prefers

ease of access to the stem plate to confirm a secure pin.

1

PIN

- The first problem is that the turnbuckle toggle didn't

stick out far enough to easily insert the pin. The toggle must

stick out reasonably far enough to

quickly pin it on the ramp. It's why I

fabricated the 3/4" spacer shown at right to push the drum up to

expose more of the toggle. I also fabricated a new turnbuckle

retaining clip (see red arrows above) that has a

longer reach up to the mounting screws. This clip holds the drum down so the jib can be tensioned

without pulling the foil up. Sounds confusing doesn't it? 1

PIN

- The first problem is that the turnbuckle toggle didn't

stick out far enough to easily insert the pin. The toggle must

stick out reasonably far enough to

quickly pin it on the ramp. It's why I

fabricated the 3/4" spacer shown at right to push the drum up to

expose more of the toggle. I also fabricated a new turnbuckle

retaining clip (see red arrows above) that has a

longer reach up to the mounting screws. This clip holds the drum down so the jib can be tensioned

without pulling the foil up. Sounds confusing doesn't it?

2

RING

- The second problem is that it is really difficult to twist

the ring through the aft pointed pin since it is difficult to see under

the low drum with my hands in the way. "Last I checked, these parts roll real easy on

the parking lot, never to be seen again!" It doesn't help

that the SJ23 tack horns block

access! I'm hesitant to remove the horns because I use them to attach the

jib sleeve zipper pull line to.

- NOTE - Regardless of

which direction the pin was installed, it always slid till the ring was

against the turnbuckle toggle. There should be no strain on the

ring as this increases the risk of loosing the pin and dropping the

mast. Nasty that is. One should be forgiven to assume all is safe by installing the pin

pointed downhill but I was really surprised one day to discover it slid

uphill in only 15 minutes while rocking at the dock. This was

immediately after a launch. See Tech Tip F34.

The obvious solution is

not so obvious after all.

The following season I replaced the pin with a

standard (1.5 x 5/16)"

bolt pointed downhill. The

extra nut and stack of washers are there to fill the space along the

clear shank.

They are glued together with Marine Goop so I don't mess with a bunch of loose

washers at launch time. The threaded end of the bolt was bevelled

so it slips easily through the stem & toggle holes without damaging the

thread. A hole was drilled across the end of the bolt to accept the locking ring.

It is now easier to slip the ring through the hole. The following season I replaced the pin with a

standard (1.5 x 5/16)"

bolt pointed downhill. The

extra nut and stack of washers are there to fill the space along the

clear shank.

They are glued together with Marine Goop so I don't mess with a bunch of loose

washers at launch time. The threaded end of the bolt was bevelled

so it slips easily through the stem & toggle holes without damaging the

thread. A hole was drilled across the end of the bolt to accept the locking ring.

It is now easier to slip the ring through the hole.

CONCLUSION - Inserting the spacer and fabricating a new

turnbuckle retaining clip saved me the effort of having to shorten the

forestay foil and possibly the genoa (Argh, neither of these are gonna

happen any time soon).

Had I known about this problem before I fabricated the

new forestay and cut the foil to fit, I would have included an extension. The trials and

tribulations of installing new hardware on my own with a boat on the

hard 15 KMs away from home."

Another thought was to fabricate a 2" extension

on top of the stem

plate using two 1/8" thick flat

bars (shown at left) or a 2" long

eye to jaw toggle (shroud extender). The top of either extension could fit inside the 3/8"

jaw of the turnbuckle toggle.

The bonus of an eye to jaw toggle is that the top pin

could go

athwart ship, as shown in the manual, making the job of pinning the

forestay easier.

The bottom bolt would stay permanent and the

top

would be removable. This is still a viable solution for others so I'll leave it

here as food for thought.

TOP

|

|

FURLING CONTROL LINE

- All furling systems use similar hardware for the furling

control line. The idea is to have as little friction in the system as

possible. FURLING CONTROL LINE

- All furling systems use similar hardware for the furling

control line. The idea is to have as little friction in the system as

possible.

-

Furling Drum - At the bow

I installed the furling control line to port so it is away from the anchor which

is to starboard.

"Make life

easy for yourself, not more difficult. I'm right handed and stand

to port when I handle the anchor line. It made sense to me." The fairlead bracket

(CF-55-22) is on the drum to guide the line on it for an even wrap. The first ball bearing swivel block is installed

just forward of the aft pulpit leg. Thereafter a SS lined fairlead is on each

stanchion post with a small ball bearing block clipped

to the toe rail between the stanchions to keep the deck clear. And finally a swivel

ball bearing ratchet block is on the pushpit to direct

the line up to the cleat.

Notice that all blocks are ball

bearing and swivel to minimize friction. I can't emphasize this enough. How to operate

a furling jib.

Furling Control Line - The system requires 40' of 1/4"

soft line which is long enough for the 150% genoa or the 110% working jib.

However, the 1/4" line spooled up against the

inside of the four drum stakes, causing friction. So it was replaced with 7/32"

line which works fine. It's important to maintain

a minimum of three warps around

the drum with the sail out.

-

Forward Block - The location of the forward block

is critical so the furling control line meets the middle of the drum at 900 to

spool evenly. Get this wrong and you'll be walking to the bow to undo

a nasty snarl.

Take a knife or marlin spike with you and quit grumbling!

This is a Ronstan full articulating, ball bearing block installed

on the toe

rail, just forward of the aft leg of the pulpit. It is a perfect spot for this. Forward Block - The location of the forward block

is critical so the furling control line meets the middle of the drum at 900 to

spool evenly. Get this wrong and you'll be walking to the bow to undo

a nasty snarl.

Take a knife or marlin spike with you and quit grumbling!

This is a Ronstan full articulating, ball bearing block installed

on the toe

rail, just forward of the aft leg of the pulpit. It is a perfect spot for this.

-

Stanchion Fairleads

- To retain as much clear walking space on the side deck, I installed a stanchion

bulls eye fairlead (Nautos 605740) on the outside. Use metal lined fairleads as

they have less friction and stand up to wear better than vinyl ones.

For the same reason use ball bearing turning blocks where needed. Stanchion Fairleads

- To retain as much clear walking space on the side deck, I installed a stanchion

bulls eye fairlead (Nautos 605740) on the outside. Use metal lined fairleads as

they have less friction and stand up to wear better than vinyl ones.

For the same reason use ball bearing turning blocks where needed.

-

Mid Deck -

Two mid deck Harken ball bearing blocks were added to keep the side deck clear and the spring line cleat

free. The last thing I

need is a tripping hazard when I'm in a hurry to scoot around the

shrouds. Mid Deck -

Two mid deck Harken ball bearing blocks were added to keep the side deck clear and the spring line cleat

free. The last thing I

need is a tripping hazard when I'm in a hurry to scoot around the

shrouds.

Cockpit - At mid cockpit I installed a tiny Harken 16MM ball bearing block

on the toe rail to keep the line low and prevent a tripping hazard. To maintain a tight

roll of the jib I installed a Ronstan RF42100 automatic ratchet block on the

bottom of the pushpit

leg. A

ratchet block works in much the same fashion as holding a line

wrapped around a winch, it maintains tension. The ratchet is automatically enabled in

proportion to line load and the force required to enable the ratchet is

adjustable at the swivel. It took very little time to adjust to this

feature and produces a neater wrap than a free spinning block.

This Ronstan block swivels so it always creates a fair lead to where

I stand. The spring under it quiets the block. The cleat

installed above it works well with the ratchet block to secure and store

the line.

If you have

the factory corner stanchion you could install a turning block there

with a cleat

slightly forward to secure your furling control line to. You'll have to

get creative here.

TOP

|

|

HOW to

REPLACE a DAMAGED FORESTAY (REPAIR 101) -

Just suppose

your forestay develops a problem and the foil can't be

removed. Now what do you do? Its always good to have a plan for

this prior to installing a furling system.

-

When you need to replace the forestay inside

the foil of your furling system, here's

a

video to replace the forestay without damaging the foil. These

guys do

a better job of showing it than I can describe it.

-

The overall length of the new forestay MUST be exactly the same length as the

previous to retain the mast rake. Of course if the rake is wrong, now is your chance to correct it.

NOTE - I have done this job on another sailboat and it was

extremely difficult to install the bottom Sta-Lok terminal due to the

short protruding wire beyond the bottom foil. My hands cramped up trying to hold the strands in place while screwing on the threaded stud. Seriously, consider removing at least the

drum and torque tube plus maybe a bottom section of foil prior to attempting this

job. It may seem like overkill but it is the best way to guarantee a correct

installation.

TOP

|

|

CONVERT the

FACTORY JIB to FURLING -

See Tech Tip F10b.

TOP

|

REMOVABLE INNER STAY (Food for Thought 2)

- While not a go fast gadget, a storm sail set on a removable inner stay,

instead of a deeply reefed roller furling jib or a storm jib slipped over

a furled jib, can keep you going in rough weather by maintaining a more

balanced sail plan. See Tech Tip F36 for more

information.

TOP

|

|

USEFUL REFERENCE LINKS (Practical Sailor)

|

|

Return

to Tech Tip Index. . . . . . . . . . . . . . . Have

a Question? |

The reliability of a jib furling system on a pocket cruiser is beneficial for a

solo sailor since reducing sail area quickly from the safety of the

cockpit is your safety valve. It eliminates a trip to a pitching foredeck that can

require a fair degree of balance in steep waves. Then there is the

issue of leaving the tiller while the boat does squirrelly things all on its own.

The reliability of a jib furling system on a pocket cruiser is beneficial for a

solo sailor since reducing sail area quickly from the safety of the

cockpit is your safety valve. It eliminates a trip to a pitching foredeck that can

require a fair degree of balance in steep waves. Then there is the

issue of leaving the tiller while the boat does squirrelly things all on its own.  halyard restrainer at the masthead," they are wrong. This is essential, unless you enjoy running up the mast to clear a wrap!

halyard restrainer at the masthead," they are wrong. This is essential, unless you enjoy running up the mast to clear a wrap!

The drum can be released from the furler housing and the side of the

housing removed to expose

the turnbuckle for adjusting. Once the turnbuckle is adjusted to the correct

mast rake the head stay tension

is set by the back stay. See

The drum can be released from the furler housing and the side of the

housing removed to expose

the turnbuckle for adjusting. Once the turnbuckle is adjusted to the correct

mast rake the head stay tension

is set by the back stay. See

tired of the "panic" trips to the foredeck to douse a jib. Then in Fall of 2017

I was offered a

tired of the "panic" trips to the foredeck to douse a jib. Then in Fall of 2017

I was offered a

Transport & Storage - For trailering and winter storage

Schaefer recommends the drum and swivel

be slid

off the foil and stored in the cabin to remove excess weight.

Transport & Storage - For trailering and winter storage

Schaefer recommends the drum and swivel

be slid

off the foil and stored in the cabin to remove excess weight.

The 2' end section that didn't want to straighten was "persuaded" to do so with a

heat gun. The top of the foil

terminates about 2" from the end of the new forestay. The

The 2' end section that didn't want to straighten was "persuaded" to do so with a

heat gun. The top of the foil

terminates about 2" from the end of the new forestay. The

The following season I replaced the pin with a

standard (1.5 x 5/16)"

bolt pointed downhill. The

extra nut and stack of washers are there to fill the space along the

clear shank.

They are glued together with Marine Goop so I don't mess with a bunch of loose

washers at launch time. The threaded end of the bolt was bevelled

so it slips easily through the stem & toggle holes without damaging the

thread. A hole was drilled across the end of the bolt to accept the locking ring.

It is now easier to slip the ring through the hole.

The following season I replaced the pin with a

standard (1.5 x 5/16)"

bolt pointed downhill. The

extra nut and stack of washers are there to fill the space along the

clear shank.

They are glued together with Marine Goop so I don't mess with a bunch of loose

washers at launch time. The threaded end of the bolt was bevelled

so it slips easily through the stem & toggle holes without damaging the

thread. A hole was drilled across the end of the bolt to accept the locking ring.

It is now easier to slip the ring through the hole.  Forward Block - The location of the forward block

is critical so the furling control line meets the middle of the drum at 900 to

spool evenly. Get this wrong and you'll be walking to the bow to undo

a nasty snarl.

Take a knife or marlin spike with you and quit grumbling!

This is a Ronstan full articulating, ball bearing block installed

on the toe

rail, just forward of the aft leg of the pulpit. It is a perfect spot for this.

Forward Block - The location of the forward block

is critical so the furling control line meets the middle of the drum at 900 to

spool evenly. Get this wrong and you'll be walking to the bow to undo

a nasty snarl.

Take a knife or marlin spike with you and quit grumbling!

This is a Ronstan full articulating, ball bearing block installed

on the toe

rail, just forward of the aft leg of the pulpit. It is a perfect spot for this.

Stanchion Fairleads

- To retain as much clear walking space on the side deck, I installed a stanchion

bulls eye fairlead (Nautos 605740) on the outside. Use metal lined fairleads as

they have less friction and stand up to wear better than vinyl ones.

For the same reason use ball bearing turning blocks where needed.

Stanchion Fairleads

- To retain as much clear walking space on the side deck, I installed a stanchion

bulls eye fairlead (Nautos 605740) on the outside. Use metal lined fairleads as

they have less friction and stand up to wear better than vinyl ones.

For the same reason use ball bearing turning blocks where needed.  Mid Deck -

Two mid deck Harken ball bearing blocks were added to keep the side deck clear and the spring line cleat

free. The last thing I

need is a tripping hazard when I'm in a hurry to scoot around the

shrouds.

Mid Deck -

Two mid deck Harken ball bearing blocks were added to keep the side deck clear and the spring line cleat

free. The last thing I

need is a tripping hazard when I'm in a hurry to scoot around the

shrouds.