| The idea for this Tech Tip came to me after a

trailer was stolen from our club parking lot. Unfortunately for the

owner who had

a very desirable low slung, heavy duty trailer that was perfect for hauling somebody's Bobcat.

Poof, gone! With crane out

scheduled for the

following weekend and old man winter just around the corner, the poor guy

was frantically looking for measurements to build a cradle to place the boat

on a flat bed

trailer. Without the critical hull dimensions for your boat it is pretty difficult

to fit it to a new trailer. Then there are those who intend to modify a

used trailer

to fit their boat. Regardless of your situation, you must know where

and how high to place the support pads to carry your boat securely with the

correct weight on the tongue and over the axle. One of

the easiest techniques is to copy another trailer. Pull up alongside

it and start taking measurements. Easy enough, if one is

available!

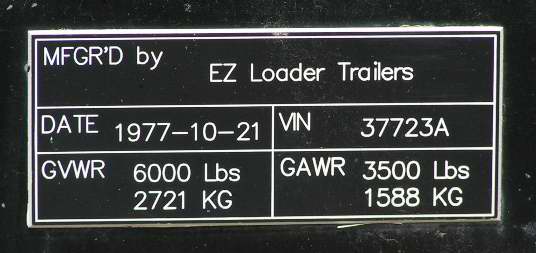

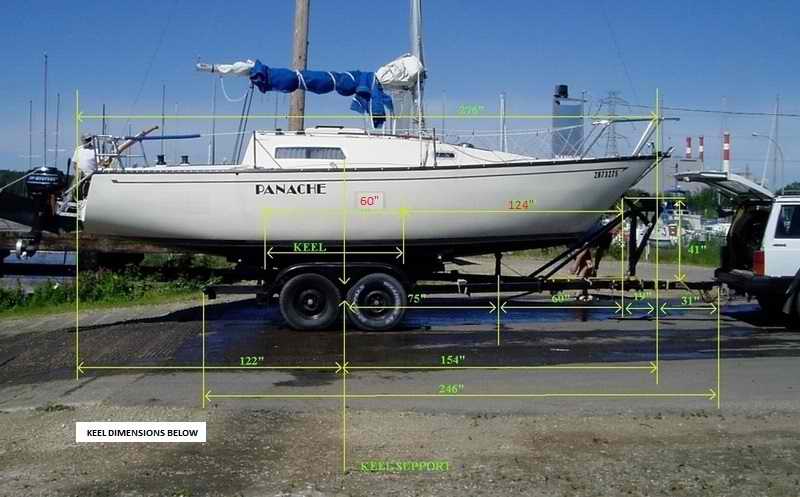

Panache's trailer was manufactured in 1979 by EZ Loader Trailers. The descriptions that follow in this Tech Tip are about this trailer. You should be able to "reverse engineer" these dimensions for another manufacturer trailer without too much difficulty. You should also

read Tech Tip A01, Desirable Features

of an SJ23 Trailer. COMPONENTS

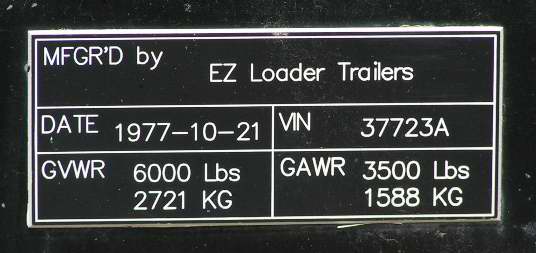

LEGALESE

& CAPACITY PLATE - The trailer

capacity plate is shown here. If you cross the 49th parallel, you MUST

have a capacity plate attached to the frame and have proof of ownership in

hand. If you don't own the trailer you better have a

signed and dated letter from the owner (include date, owner address and phone

number) giving the named borrower permission to use trailer registered with VIN# till and end date. In the

body of the letter state where you are going,

the purpose of

the visit and how long you intend to be on the other side of the border. Customs

people can be real picky, so smile when they ask you. LEGALESE

& CAPACITY PLATE - The trailer

capacity plate is shown here. If you cross the 49th parallel, you MUST

have a capacity plate attached to the frame and have proof of ownership in

hand. If you don't own the trailer you better have a

signed and dated letter from the owner (include date, owner address and phone

number) giving the named borrower permission to use trailer registered with VIN# till and end date. In the

body of the letter state where you are going,

the purpose of

the visit and how long you intend to be on the other side of the border. Customs

people can be real picky, so smile when they ask you.

OVERALL WEIGHT - An SJ23 requires a minimum of four support pads or two long bunk boards on the trailer, a keel

support and a V-block or roller on a "winch tree" to pull the hull up on

the trailer and to stop the hull when braking.

Assuming the total weight of an empty SJ23 is 2700 lbs, of which 960

lbs. is ballast, the 4 support pads must each carry 435 lbs. or each bunk board

870 lbs

and the keel support will hold 960 lbs. Simple enough math

but somewhat difficult to measure with a scale. In addition to this weight you

should allow for about 500 lbs of "stuff" on board,

rigging, rum, gum, scotch, food, beer, a life jacket,

basically all the

staples needed to sustain life! One final point, some SJ23s came out

of the factory heavier than the ~2700

lb. design limit. So heavy that they required a tandem axle trailer.

Yours may be one of them so don't rule this out.

LIGHTS - An SJ23 trailer requires

three types of illuminated lights if it is to be towed on a public road; signal

lights (brakes, left & right), a band of 3 horizontal lights in the center of the frame indicating it is wider than 80", clearance lights to mark the width of the trailer

to passing and opposing vehicles and a licence plate light. I'm not sure if clearance lights are required on the fenders, being the widest part of the trailer. In my experience fender lights take a beating so I use passive reflectors. Regardless, orange in front and

red to the back. See Tech Tip A08 for electrical maintenance.

AXLES & SUSPENSION - This EZ Loader frame is made of (3x4)" rectangular steel tubing 1/8" thick with all components bolted together. It was factory equipped with a single 3500 lb. (1588 Kg) straight axle on springs equipped with 10" electric brake drums. When radial tires finally appeared on this continent I installed the

highest load rated tires that could fit the rims, P235x75R15. This

combination can support an empty SJ23 but it is close to its limit. This is

one of the

reasons why I converted the trailer to tandem 3500 lb. axles. See

Tech Tip A04 and A03 for a

description of the conversion. If you want a tandem axle then each

axle should have a GAWR rating of >3500 lbs (1588 Kg), not 2000 lbs. If

a tire blows on a 3500lb. axle then the other axle has a fighting chance to

support all the weight till you stop. Brakes are mandatory with a GVWR

of 6000 lbs. All wheels have drum brakes. AXLES & SUSPENSION - This EZ Loader frame is made of (3x4)" rectangular steel tubing 1/8" thick with all components bolted together. It was factory equipped with a single 3500 lb. (1588 Kg) straight axle on springs equipped with 10" electric brake drums. When radial tires finally appeared on this continent I installed the

highest load rated tires that could fit the rims, P235x75R15. This

combination can support an empty SJ23 but it is close to its limit. This is

one of the

reasons why I converted the trailer to tandem 3500 lb. axles. See

Tech Tip A04 and A03 for a

description of the conversion. If you want a tandem axle then each

axle should have a GAWR rating of >3500 lbs (1588 Kg), not 2000 lbs. If

a tire blows on a 3500lb. axle then the other axle has a fighting chance to

support all the weight till you stop. Brakes are mandatory with a GVWR

of 6000 lbs. All wheels have drum brakes.

The trademark construction of EZ Loader

trailers is to bolt all components

together so it can be adjusted to support

most any shape load and weight. Welding may be cheaper than bolts but you'll

appreciate the bolts if you ever have to adjust anything. This feature

has its price which means you have to inspect the nuts on a regular basis. I

use an old race car technique and applied a dab of silicon sealant between

each nut and the exposed thread. That ended my worry of nuts turning

loose. Checking the trailer annually should be part of your routine

safety inspection. BREAK-AWAY SYSTEM - See Tech Tip A01.

FENDERS - There are two sets of steel straps to support the tops of the

fenders and two more at the bottom of each fender, one at the front and the other at the back.

You can just see a set inside the left fender above. With

four straps supporting each fender they no longer vibrate at highway speed. I

don't allow anyone to step on them, including myself! That's what the aluminum ladder lashed along the

front of the trailer is for.

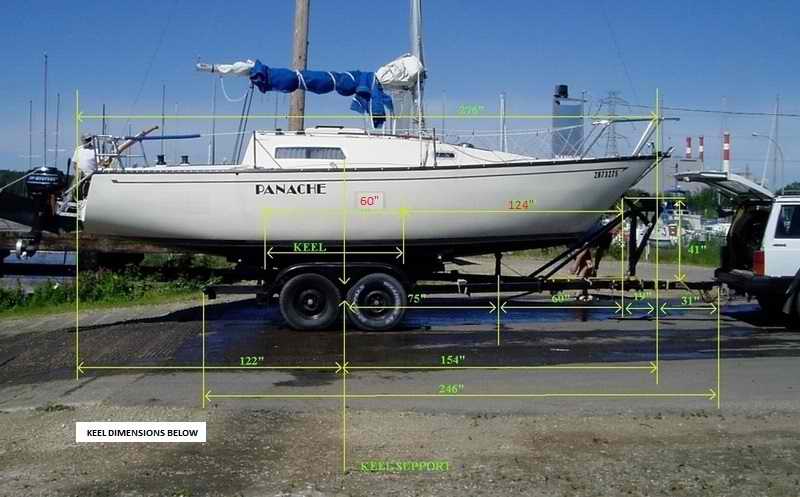

KEEL

SUPPORT & GUIDE - The combination keel support, (1.5x3)" steel tubing with

keel guides, is visible in the center of the trailer above.

The bottom of the keel guide is lined with soft cedar and the vertical sides are lined with slippery UHMW. Since the keel

support bar is adjustable (up/down) with the crank shown at right, I raised the bar up to the keel to support ~600 pounds of it. This offsets some of the weight on the support pads and the hull. Thus I have correct dimensions between the keel support and the hull pads. For reference purpose, the bottom of the

keel rests just below the bottom of the trailer frame. KEEL

SUPPORT & GUIDE - The combination keel support, (1.5x3)" steel tubing with

keel guides, is visible in the center of the trailer above.

The bottom of the keel guide is lined with soft cedar and the vertical sides are lined with slippery UHMW. Since the keel

support bar is adjustable (up/down) with the crank shown at right, I raised the bar up to the keel to support ~600 pounds of it. This offsets some of the weight on the support pads and the hull. Thus I have correct dimensions between the keel support and the hull pads. For reference purpose, the bottom of the

keel rests just below the bottom of the trailer frame.

NOTE - I judiciously grease the thread so it is

easier to raise the bar to full height. If I eat my Wheaties in the morning I can

jack the hull up off a pad to slip cardboard in the gap. I think the original owner of the trailer added this bar. The hand crank is strong but has all the hallmarks of a DIY garage mechanic. Its a nice feature. GUIDE POSTS - Guide posts service to direct the floating hull over the trailer so the keel support can grab the keel thereby ensuring perfect positioning on the trailer. See Tech Tip A01.

SUPPORT PADS or BUNK BOARDS - Panache's EZ Loader Trailer is equipped with four fully articulating support pads that each consist of two pressure treated (2x4)"s that you can see above. Each pad can rock left/right on top of its mounting post to rest flat against the hull for its full surface. Each pair of posts can rock fore/aft on a common cross bar hinged from the bottom of the side rails. Together they align perfectly to the hull. Each post can be adjusted left/right for a fine alignment to the hull. In addition, each (2x4)" can be rolled independently to fit flat against the hull. Once the (2x4)'s are aligned I locked them for stability and ease of launching.

There is such a thing as too many adjustments on the launching ramp! This is definitely a time to leave well enough alone.

I calculated that the four pads actually provide more support than two full length 6" bunk boards due to their large contact area with perfect alignment.

|

EZ LOADER TRAILER SUPPORT POST PARTS |

- Each support post consists of 2 square tubes with an internal threaded rod to adjust the height.

- The bottom outer portion of each post is

welded to a 1/4" thick mounting plate, angled about 200

toward the hull to align the forces down the post. The plate is bolted on a cross bar so they can be spaced left/right to match the width of the hull.

- Each inner portion of the post is made of 2" square tube with 1/8" thick wall that can be adjusted

up/down and locked inside the bottom outer portion.

- Each of the two 4" square cross bars rotate on end joints, one under

each side rail as shown below. This is how a set of pads rock fore & aft.

- Each pad rocks sideways on factory UHMW bearings. Don't over tighten the bearing or you will crush it. It should be just loose.

- Each (2x4)" pad rocks on 2 bolt hinges to align to the hull. Lock these bolts once aligned.

- The rotating joints result in pads that perfectly align to the

hull shape.

|

Fig 1, Pivots - The trailer cross bar hangs and pivots from the rails. The boat is supported by just these four bolts. Lubricated annually with ATF to prevent rust.

|

Fig 2 -

|

Fig 3, Pad Post - Pad post adjusts up/down (top bolt) and locking nuts (horizontal). I try to keep the vertical threaded rod lubricated with ATF. Never know when one has to be adjusted with the weight of the boat on the pads.

|

Fig 4, Pad Support Post -

Pad support post adjusts left/right along the cross bar.

Fig 5, Pad Adjutsment - Pad adjusts (fore/aft) over the pad post.

|

Fig 6, Pad Support Post - The photo at right shows the pad support post removed revealing the threaded rod that adjusts the height of the post. The tube over the rod limits upward position. Don't remove it. The wing nut below is the factory modified one that goes on the bottom of the threaded rod, not the dual wing nut shown at right. EZ Loader removes one wing from the nut so the short side points to the inside corner of the outer section of the post. The remaining wing prevents it from turning as it gets pushed against the inside of the post. This is the clever trick that allows a person to adjust the length of the support post from the top only as shown above. It pulls the inner tube up or lets it slide down after you release the locking nuts. Very clever. By the way, this job is best done with the weight off the support pad. It goes without saying that the thread should be lubricated. Robert H.

|

Fig 7, Height adjuster -

|

TRAILER WINCH

TREE & BOW ROLLER - I beefed up the original flimsy winch tree because I thought it wasn't rigid

enough to pull the hull up the trailer or support the bow. It wasn't difficult to visualize the boat coming through to my "glove compartment" during hard braking. The second reason was to

stiffen the frame for road hauling. I've always wonder about those pathetic winch posts without angle bracing. In reinforcing the tree I replaced the short post with a taller one to raise the winch above the boat trailer eye. This so the boat trailer eye can fit snug under the tree roller.

See

Tech Tip A01. TRAILER WINCH

TREE & BOW ROLLER - I beefed up the original flimsy winch tree because I thought it wasn't rigid

enough to pull the hull up the trailer or support the bow. It wasn't difficult to visualize the boat coming through to my "glove compartment" during hard braking. The second reason was to

stiffen the frame for road hauling. I've always wonder about those pathetic winch posts without angle bracing. In reinforcing the tree I replaced the short post with a taller one to raise the winch above the boat trailer eye. This so the boat trailer eye can fit snug under the tree roller.

See

Tech Tip A01.

In this photo I'm slipping the jib downhaul ring over the forestay after we stepped the mast. I tend to forget this job at the ramp. This is a long time before I added roller furling to Panache. BOW SUPPORT ROLLER - The 8" wide roller shown

under the bow below works in conjunction with positioning the trailer eye under the roller. It is an important addition I added a few years later. It guarantees perfect fore aft positioning of the hull for every haul out regardless of

the slope of the ramp. See

Tech Tip A01 for a description. It was installed ~6' back from the boat trailer eye.

DRAW BAR - EZ Loader designed this trailer with a single draw bar.

The overlapping joint that connected the draw bar to the side rails was too weak due to being only 20" long.

Probably adequate for the power boat this trailer was designed for but

woefully inadequate for the 2700 lbs. of sailboat it now carries. This joint

flexed too much for my liking so I replaced the original 60" long draw bar with a 124" bar,

creating an overlapping joint of 64". The inboard end of the draw bar is U-bolted to a new cross member of angle iron that is also U-bolted to each side rail. As a result the joint no longer flexes.

About 1.5' forward along the draw bar is another cross member where the new roller was installed to support the bow.

I was able to install a fixed height roller to fit

the spot because the

rest of the pads were already adjusted correctly. If the pads weren't correct the roller height would have been adjustable.

Since the longer draw bar

sticks out ~2' further at the front I can

push the trailer deeper into the water. I could raise the tailgate of my Jeep Cherokee while attached to the trailer and now drop the tailgate of my Tacoma. The extra

walking space between both vehicles sure

makes life easier on the loading ramp. It tows more stable at highway speed.

HITCH - The 2" coupler is not of much interest to this Tech Tip

except that you should be concerned if the coupler is only welded to the

frame. Some welds look pretty but aren't strong. It takes a

trained eye to know the difference. Therefore, it's a good

idea to back up the welds by thru bolting the coupler to the draw bar. The bolts are a good backup to welds that can rust. With the single draw bar configuration of this trailer, the

only benefit an equalizing hitch offers is load distribution of the tongue

weight. While this works well, there is no roll stability since the torsion bars

are parallel to each other. I thought the lack of roll stability might limit the towing

performance but it hasn't. This could be because the maximum speed I tow is 100

K/H (60 M/H)!

SECURE THE HULL FOR TOWING - When

towing the hull should always be strapped to the trailer with a couple of cargo

straps. This nylon webbing is rated to 12,000 lbs and the ratchet ensures

that the strap stays snug. The aft strap goes

around the hull, just

behind the cabin, and under the trailer frame. The forward strap goes

around the hull where the deck house meets the deck, and then under trailer frame. The trailer winch line is snugged up

tight and the safety chain is clipped to the boat trailer eye. I also tie the boat trailer eye downward around the tree to prevent

the bow from bobbing up off the trailer. This is an easy one to

forget but oh so important to keep the stem in the V block or in Panache's case, the roller.

While cargo

straps

can keep a boat on the trailer, it's

also wise to grab a bag of common sense when towing a boat! Tow no faster than 100 K/H (60 M/H),

observe the posted speed limit for a corner, know the overhead clearance required

AND read the overhead clearance sign ahead of you. Think this through! And lastly, remember to stop for ice cream! See

Tech

Tip A02.

MAINTENANCE

- NUTS & BOLTS - All the components on an EZ Loader Trailer are bolted together for easy alignment to different hull shapes. With routine dipping in water the nuts will seize on the thread. This makes it near impossible to twist a nut to adjust the trailer. For this reason I dribble ATF on the thread around each nut. I include the lug nuts on the wheels which is a lesson I learned when helping a guy with a flat tire on the highway.

- PAINT - The real reason for a coat of

paint is to prevent rust. The fact that a fresh coat impresses the dock watchers at the ramp is another issue all together. Panache's trailer was painted white from

the factory and it always had rust spots. So I knocked the

rust off, treated the spots with rust converter and painted the trailer black with semi-gloss Tremclad. I chose black because the sun heats it very quickly which dries

the metal. Dry metal means no rust. I chose semi-gloss because dust doesn't stick to it as well as flat and is slightly easier to see in the dark. The trailer gets a thin coat of paint every 5 years and I've had little rust since. By the way, the ONLY way to

paint a boat trailer is with a spray gun and it only takes half an hour.

I will guarantee you at least half a dozen shin bruises and cut knuckles if

you use a brush. Don't ask! TOP

TRAILER

DIMENSIONS & POSITION of SUPPORT PADS for CORRECT WEIGHT DISTRIBUTION.

(A huge debt of gratitude goes to the guys who helped proof read these

dimensions).

Hull Fore/Aft Position Relative to the Axles - To provide adequate hitch weight for stable towing,

position the mid point of the hull (front of the large window) directly over the axle of a single axle trailer

or over the walking bar (between axles) of a tandem axle trailer.

Keel Support Bar Relative to the Hull - The keel support bar is

positioned midway between the axles or the front of the large window.

This

is at the maximum girth of the keel which is 7.5" wide.

The boat rests on the trailer with the bottom of the keel flush with the

bottom of the frame.

Trailer Bow Roller Relative

to the Boat Trailer Eye - For

easy, quick hassle free ramp launching you want the boat trailer

eye to rest snug UNDER the roller on the tree when the boat is level on the trailer.

Therefore the winch line goes

UNDER the roller. This allows the boat to slide into the

water unimpeded during launch time. (In the 1990s I replaced the

V-block with a roller to reduce wear and friction. See

Tech Tip

B26. I had to build a much taller and beefier tree to raise the winch above the boat trailer eye.) The added advantage is that when the boat trailer eye is resting UNDER

the tree roller, you know the boat is positioned correctly on the trailer.

A very convenient reference mark when retrieving on the ramp. In addition, the trailer tows quieter when the boat is snug up against the winch tree.

The winch must be

placed a few inches above the roller so the hull is pulled up and forward

as it is comes to its final resting spot on the trailer. The

pivot bolt of the winch measures at 41" above the frame. The boat is retrieved by floating it on the trailer as the

winch and boat trailer eye cannot pull 3000+ pounds of weight up the support

pads. There is too much friction for that much weight. See

Tech Tip B26.

(Measurements shown below are to position the

hull on the trailer)

________________________________________________

IMPORTANT - DO NOT make your trailer to the

exact dimensions

shown below.

I tried to take accurate measurements but since I was measuring on my own, they

are likely off a bit. So allow for adjustments to fit the hardware to your boat.

|

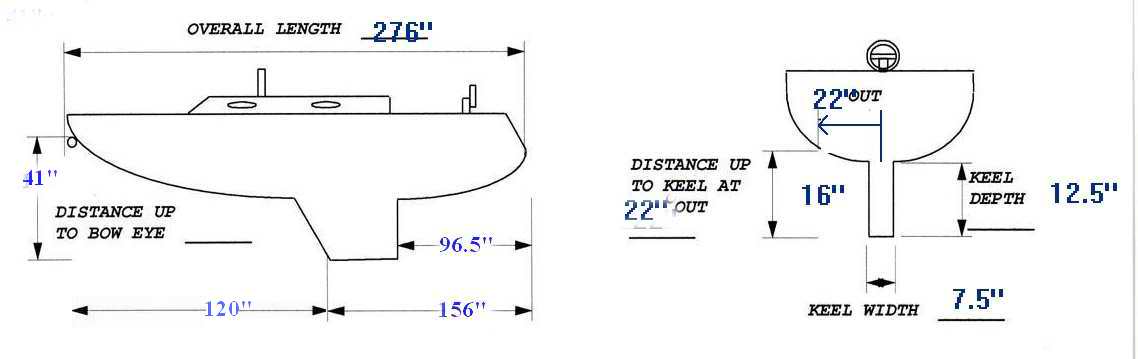

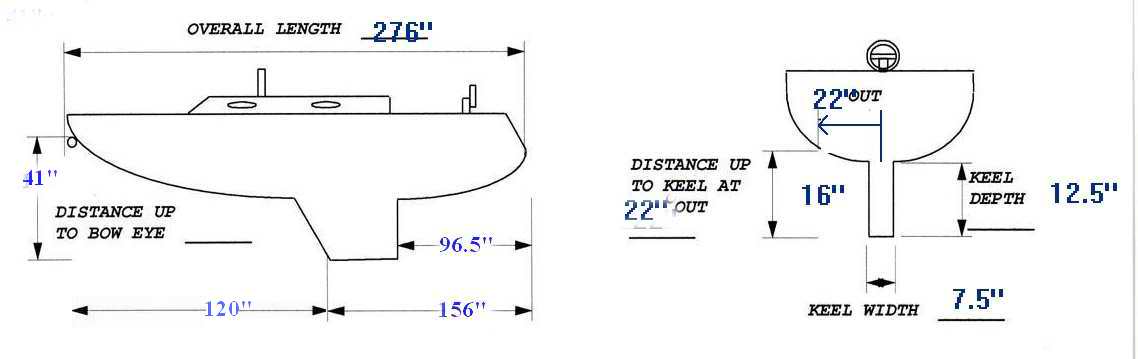

HULL MEASUREMENTS |

|

LOA = 23' |

SUPPORT PADS - Distance up to hull @

22" from center line = 16" |

|

Up to Boat Trailer Eye = 41" |

Distance from center line =

22" |

|

Transom to front of Keel = 156" |

Keel Width = 7.5" |

|

Transom to back of Keel = 96.5" |

Keel Depth = 12.5" |

|

Total Hull Weight = 2700 lbs (dry),

~3200 lbs (with gear). |

Stuff Onboard about 500 lbs |

|

Vertical Clearance - 9'

(you need to know this for garage door, under a bridge, etc.) |

The four

support posts on my trailer form a rectangular box that is approximately (48 x 70)"

and 16" deep, relative to the bottom of the keel. The keel

support resides at the bottom of that 16" deep "box".

-

PADS FORE/AFT

- The posts, or centers of the pads, should be about 70" apart (front to back)

so the weight is distributed equally over the front/back pads.

This is a compromise to support the hull without a keel support. This would make a bunk board about 94" long. This spacing optimally supports

the keel and overhanging ends. Relative to the boat, the center of

the front pads touch the hull 1 foot aft of the mast

step and the back pads under the companionway bulkhead. These

proportions work in conjunction with having an adequate support under the 900 lb.

keel so the hull is relieved of having to carry the ballast. Having

adequate support for the keel is very

important for long-term storage and is probably THE best reason to empty

the boat while it's on the trailer.

-

PADS SIDEWAYS

- The posts should be about 44" apart (across the

trailer) so the hull doesn't rock sideways. Any

wider than this and the pads provide too much lateral support and not

enough lift. The posts could spread apart with the hull crunching down through

the middle.

-

PAD HEIGHT - The front and back pads must be approximately 16"

high relative to the bottom of the keel. Leave room to adjust the

height of the pads.

-

KEEL SUPPORT - The keel support bar must

be just above the top travel of a single axle so it does not stop the

upward travel of the axle. It can be placed between the axles if

you have a tandem axle trailer.

NOTE: Every

towing combination is unique. The

above dimensions are from my trailer and will get you in the "ball

park" for yours. They suit

the hauling requirement of my short wheelbase

Jeep Cherokee equipped with 4L engine and 5 speed. Since I replaced it with a 5 speed automatic Toyota Tacoma, towing is much smoother and easier. To date there are three

copies of my trailer rolling around out there. My trailer tows very stable at 100KM/H (60M/H)

and you have absolutely no reason to go faster than that! TOP

ALIGN THE SUPPORT PADS - The

simplest method of guaranteeing proper weight distribution is to align the

pads to the hull, something that cannot be done with the boat off the trailer. Failure to do this correctly will result in

straining the hull around the support pad and quite likely damage it over

the long term. Note Glen's comments below.

"A frequent failure on an SJ23 are the flimsy, non-structural bulkheads adjacent to

the mast compression post. These bulkheads are mostly a divider between

the V-berth and the settees. This joint often fails after a few big bumps going down the road on a

trailer. Another area that tends to be soft is the centerline of the floor just aft of the keel. This area has no substantial bulkhead to

help stiffen it. Trailering, grounding, or sailing could transfer a

keel load up into the deck or cockpit. Having a boat sit on a trailer with excessive keel loads for a long time in hot summers

allows the boat to essentially melt onto whatever trailer form is beneath

it. All fibreglass boats do this. A repair trick for big dents is to heat

the surface with a heat gun and the tooling memory usually returns the hull to the

original shape. Then you fix the trailer!" Gleno.

- See

Tech Tip B28 for

someone who repaired a dented SJ23.

There are three key factors to align the four pads or two bunk boards

correctly so the hull weight is distributed equally amongst them.

- PAD POSITION - If the pads are too close together

(side to side) the boat will rock sideways at highway speed. If the pads are

too close together (front to back) then the boat will hobby horse going down the

road. Position any of them too close together and the hull may

roll off the trailer if stopped too hard or angled too much on the launching

ramp. Either situation is wee bit disconcerting, to say the least.

-

PAD HEIGHT -

The support pads on some trailer are so out of adjustment with respect to the height of

the hull that you have to wonder what damage is being done. When someone reports

this problem it is usually about a vessel that has been neglected

for a "zillion years" in a barn somewhere. The person

usually

adds that there is a definite depression in the area of the rollers and

the hull is pushed in a bit (soft or mushy). The

worst situation is when one of the pads is higher than the rest. It

holds more weight and pushes harder into the hull. Not good. Conversely if one pad is lower than the rest, the hull is

inadequately supported in that quadrant. Bunk boards are equally as guilty with this problem.

The source of this problem is somewhat perplexing because if

the hull is symmetrical (left to right) and touching the hull, then why aren't the pads set to

equal height? Especially since it's fairly easy to adjust the pads to

the hull when the boat is sitting on the trailer. In fact, this is the

best time to make those minor adjustments, to make her sit just so.

You can resolve this problem by measuring the height of the pads when the boat is

off the trailer. It will confirm that the pads are equal height and therefore

supporting equal weight. Mine

looked OK until I measured them, only to discover that both starboard

pads were 1" lower than the port pads. No wonder the boat couldn't

sit level when centered on the trailer. This demonstrates how

deceptive this problem can be. Measure, don't assume. Then sometimes I see a hull that

sits so crooked on a trailer that you have to wonder about who loaded

the boat or why this was done. This problem is more associated with the operator

than with the design of the trailer as it is due to poor placement of the

boat on the support

pads or using pads without adequate padding. It looks so pitiful and it's such a

shame to abuse a good craft like a San Juan sail boat.

-

PAD SIZE

- Rollers, while

convenient for launching, are generally too few or too small to

adequately support a fully loaded sail boat. The pounds per square

inch loading on rollers is too high

for long term storage. This

is why support pads or bunk boards are used for a sailboat. On most trailers the size of the pads are within the pounds per square

inch rating of the hull.

BOAT OFF TRAILER - I rocked the boat on my trailer after my alignment

described above and wasn't satisfied the pads were supporting the boat

equally. A quick trip hauling the boat down the highway confirmed this.

I could almost slip my hand between one pad and the hull. Obviously

the hull was moving on the trailer and not settling well. Something

was out of whack and it is difficult to assess the pads with the boat on the

trailer.

The following steps

describe how I fine tuned the height of the support pads after the boat came off the trailer. You can use my

final dimensions in step 5 as a starting point to adjust the pads on

your trailer. When you measure the height of the support pads;

-

If the ground

is absolutely flat and level, like an aircraft hanger, you can measure the

height of the trailer frame and each pad from the ground.

Park the

trailer on smooth level pavement or concrete and measure the frame to

ensure it is parallel to the ground, fore/aft & sideways. This is assuming the frame is not twisted, same size tires all around and all springs are at the same height. If the ground is rough you have to measure the pads with respect to the top of

the frame. A lot more difficult to do.

-

To confirm that the

trailer frame is straight and on an even plane (not twisted), measure the

distance from the ground to the top of the frame, all around the trailer.

If all measurements are the same, you have a straight frame. It's amazing the

number of twisted trailers out there. Another measurement that could be made is to stretch two strings diagonally

across the frame. If the strings just barely touch at the crossing, you

have a very straight frame. This is an extremely accurate method but it

is difficult to find a couple of clear shots across the trailer for the

strings. It's worth

doing though, if for no other reason than a check.

-

Confirm that the side

rails are parallel (left/right) to each other by measuring the distance between them.

Many single axle trailer frames are not parallel because it is not as critical.

It is absolutely imperative

that the side rails of a tandem axle trailer be parallel.

-

If the trailer frame

is straight and the rails are parallel, you can safely measure the

height of the pads from a straight edge placed across the frame, which

is now a very accurate reference, or the ground if it is absolutely flat

like a hanger floor.

-

The centre of each support pad should be

about 19" (+ or - 2") above the bottom of the keel.

After this initial alignment

followed by another with the boat on the trailer, the hull has never moved

on the pads as I travel down the road. It just settles in there

and stays. Sure makes for relaxed driving. After this initial alignment

followed by another with the boat on the trailer, the hull has never moved

on the pads as I travel down the road. It just settles in there

and stays. Sure makes for relaxed driving.

It should be noted that Panache's trailer is equipped

with four fully articulating support pads, a

trailer bow support roller, an adjustable keel support bar and a very sturdy roller on the tree. The

dimension of each "pad"

is (14x36)" and consist of two lengths of pressure treated (2x4)" covered with Astro Turf (bottom left open).

The full articulating feature ensures they align perfectly to the hull

at all stages of a ramp launch.

I

can't emphasize enough how important it is that the pads align to the

hull. The trailer is extremely stable at highway speed. TOP

Happy Hauling.

|

After this initial alignment

followed by another with the boat on the trailer, the hull has never moved

on the pads as I travel down the road. It just settles in there

and stays. Sure makes for relaxed driving.

After this initial alignment

followed by another with the boat on the trailer, the hull has never moved

on the pads as I travel down the road. It just settles in there

and stays. Sure makes for relaxed driving.